18/10/18 15

DRAWN

CHECKED

ENG APPR

MGR APPR

Classe di tolleranza*:

ISO 2768-M

*Ove non diversamente specificato

NAME

Tech. Dept.

DATE

01/10/14

NAME:

SIZE

A2

FILE NAME: asmCORRETTOnew.dft

SHEET 1 OF 1

Material:

Name?:Material

Spessore:

asmCORRETTOnew

PROJECT:

Raggio di piega

R=1.3

Cava V10

Tutte le pieghe si

intendono a 90°

dove non

diversamente

specificato

35

-4

0

mm

25-

30

mm

UKUNDA

SIG AH

Heat Recovery unit

Installation-Operation-Maintenance

reserves the right to change the specifications of the product at any time without prior notice

To prevent heat exchanger freezing, in winter, the ventila-

tion unit has anautomatic flow unbalancing system.

Temperature sensors measure the air temperature before

entering the heat exchanger and if necessary, the air flow

coming from outside is temporarily reduced.

The flow unbalance activates with downstream tem-

perature <= 3°C and the fresh air flow rate is decreased

proportionally to reach a safe temperature at the way out

the heat exchanger side exhaust air.

The maximum flow unbalance permitted is 75%.

The unbalancing cycle has a 20 minutes time duration.

For very low temperature (<-10°C) the accessory pre-

heater to heat up the outdoor air is recommended.

Protect the condensate drain from freezing in the winter

months with insulation or provide the pipe with trace

heating.

9 FROST RISK

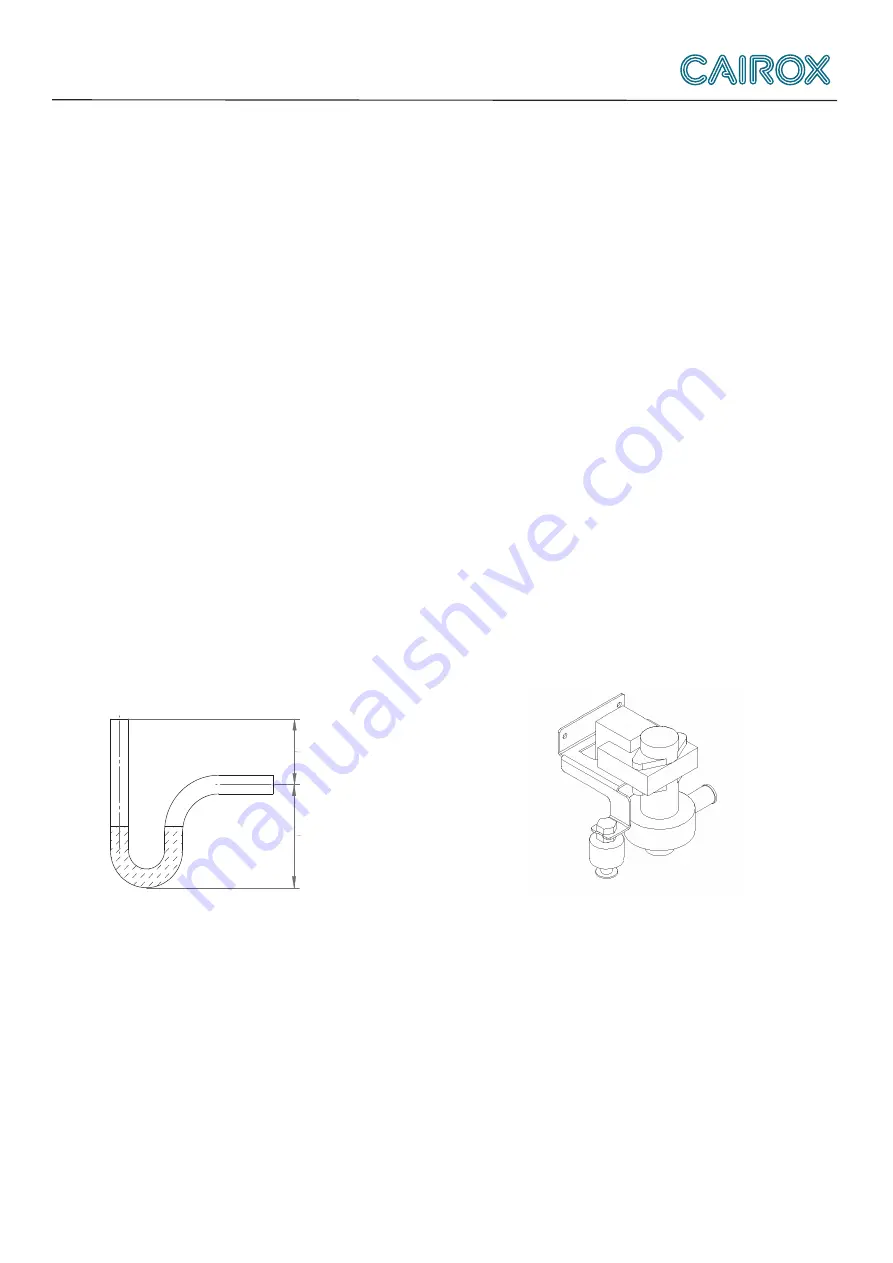

It is important that the air handling unit is installed hori-

zontally. The condensate drain must be connected to a

site drain / siphon with water trap or an on-site conden-

sate pump.

During operation there may be a negative pressure up to

500 Pa (equivalent to a 50mm water column) enter in the

flow. In this case, the difference in height must be 50mm

minimum in the siphon.

Follow the indication on illustration to choose the height.

The condensate drain must be airtight from the unit until

the siphon so that the condensation water can be freely

discharged from the device.

Is not airtight the condensate drain, false air is sucked

into the condensate drain, and the condensed water can

be derived from the device.

The unit is equipped with a water pump (internal) .

The manufacturer can not be held responsible for any

damage occurring due to non-compliance with the pro-

visions. The siphon must be installed at the exit of the

pipe from the unit. A constant slope of at least 1cm / m,

frost-free must be ensured up to the final discharge. Pro-

tect against freezing until the end of the air is over. The

installer is responsible for ensuring that the condensate

drain is free from frost.

Important! Check one day before winter start-up, whether

water is in the condensate hose.

10 CONDENSATE DRAIN

sizing of siphon

operation pressure

in [Pa]

diveded by10 =height in [mm]

operation pressure

in [Pa]

multiplied by0.075 =height in [mm]

internal condensate pump