7

FIELD PREPARATION AND OPERATING TIPS

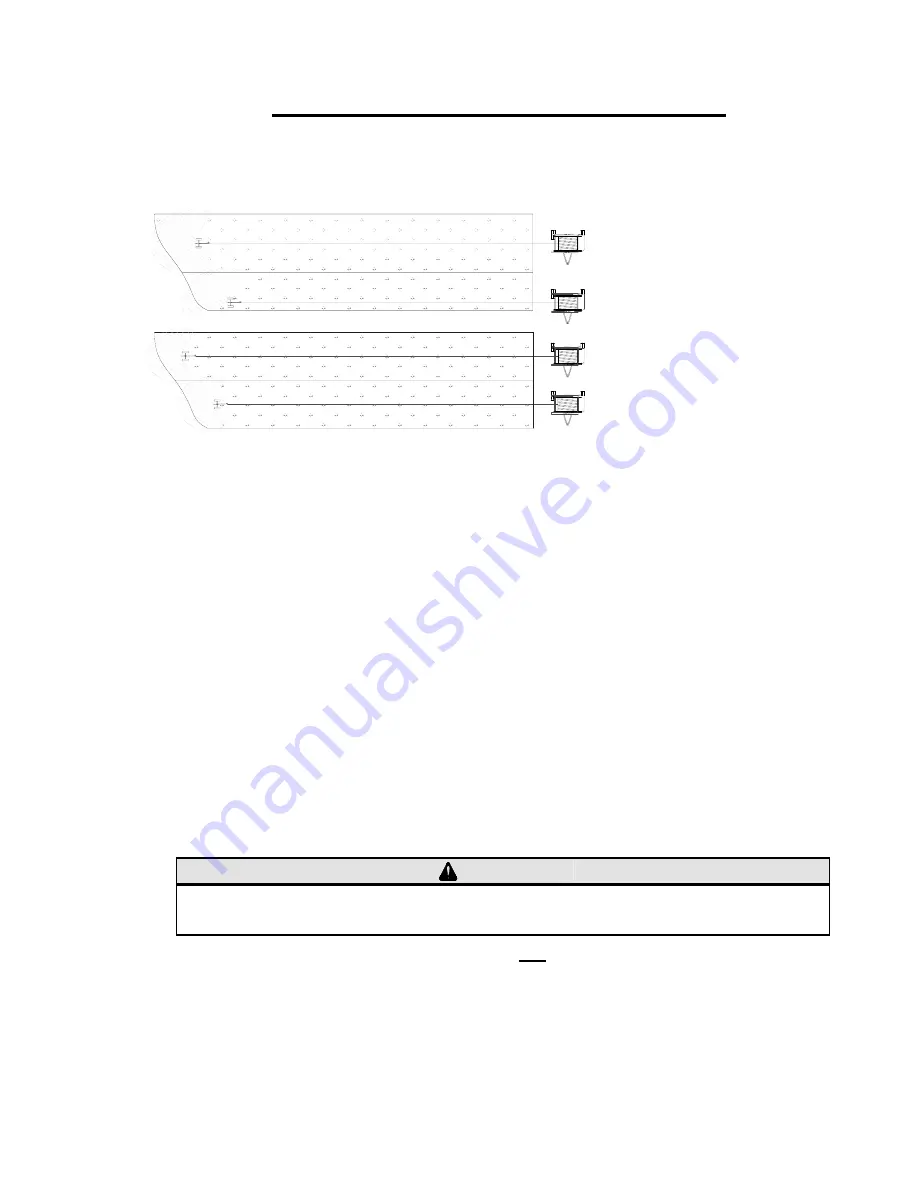

1 If your field width is greater than can be irrigated in one (1) pull but narrower than two (2)

pulls, divide the field into two (2) equal width pulls instead of one (1) full width pull and one

half width pull. (see illustration below)

There are two (2) reasons for this.

•

Even division of the field allows

maximum versatility to combat

rising winds from any direction.

•

The gun cart will track straight

and be less affected by gun

thrust.

During quarter circle operation (from the edge of a field), gun thrust tends to steer the

gun cart in the direction in which water is being thrown. This occurs when the gun is nearly per-

pendicular to the hose lane. If conditions dictate that a quarter circle pass is unavoidable, pre-

pare the travel lane by preparing a shallow trench for the hose and the cart wheels to follow.

Adding extra weight to the rear of the gun cart is also beneficial. If these preparations are not

possible or prove inadequate, reduce the size of the gun nozzle to reduce the amount of thrust.

Remember to adjust the retrieve rate to maintain your desired application rate.

During normal full pattern operation, (the gun operates to both sides of the cart) gun

thrust will correct this steering action automatically. The side to side movement of the cart

should be no more than the width of the cart’s rear wheels.

2 If you typically hill your row crops and plan to leave open travel lanes, hill and cultivate your

travel lanes as well. The absence of grass and weeds will dramatically reduce the amount of

towing effort and traction required to pull out the hose. The hills will also help guide the hose

and cart through the field.

3 Crops such as sod, alfalfa, potatoes and peas provide a great deal of resistance to pulling

the hose. If you irrigate such a crop, consider uncoupling the feeder hose at the mainline

valve and pulling out the hose slightly slower. This expels a good deal of the water from the

P.E. hose, reducing the amount of towing effort required.

4 I

f

a curved pull is necessary,

pull a minimum of 200

feet of hose

straight out from the ma-

chine chassis before beginning a long gradual curve.

5 Provide for ample head land (lane way) space to allow the machine chassis to be pivoted

and setup.

6 Where field conditions permit, always attempt to pull the hose either up or down sloping ter-

rain instead of operating on a side hill. If a side hill condition is unavoidable, provide a hilled

trench as a guide for the hose and add extra weight to the gun cart to prevent upset.

P R E F E R R E D

CAUTION

Several hundred gallons of water can be expelled. Exercise good judgement to

prevent excessive muddying of the area near the chassis of the machine.

Содержание 3250XL

Страница 1: ...3250XL 3750S 4000SA 3750XL 4000S WIDE BODY CADMAN TRAVELLER OPERATOR S and PARTS MANUAL 2001 EDITION...

Страница 2: ......

Страница 4: ......

Страница 6: ......

Страница 16: ......

Страница 26: ......

Страница 28: ......

Страница 30: ......

Страница 32: ......

Страница 34: ......

Страница 36: ......

Страница 38: ......

Страница 40: ......

Страница 42: ......

Страница 44: ......

Страница 46: ......

Страница 48: ......

Страница 50: ......

Страница 52: ......

Страница 54: ......

Страница 56: ......

Страница 58: ......

Страница 60: ......

Страница 62: ......

Страница 64: ......

Страница 66: ......

Страница 68: ...Notes...

Страница 70: ......