17

4.4

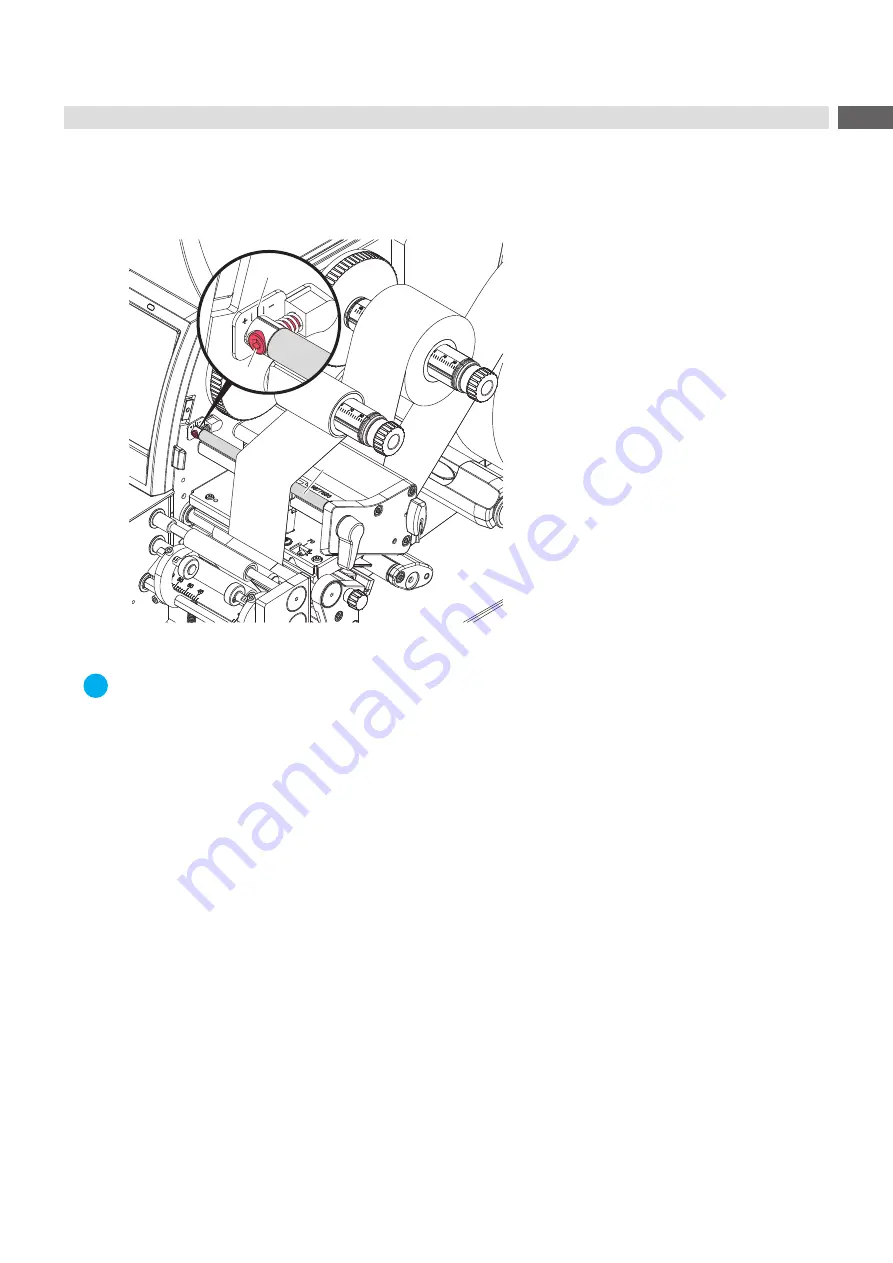

Setting the Feed Path of the Transfer Ribbon

Transfer ribbon wrinkling can lead to print image errors. The transfer ribbon deflection (3) can be adjusted so as to

prevent wrinkles.

1

2

3

Figure 16

Setting the feed path of the transfer ribbon

i

Note!

The adjustment is best carried out during printing.

Read current setting on the scale (1) and record if necessary.

Turn screw (2) with Allen key and observe the behavior of the ribbon.

In the + direction, the inner edge of the ribbon is tightened, and the outer edge is tightened in the - direction.