17

6.2

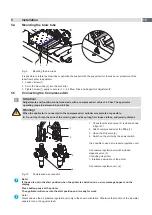

Blow Tube and Support Air Adjustments

Adjust the support air that the label can constant without swirl come to the pad from the dispense edge of the printer.

All blow tube holes which are over the broadness from the label must be covered.

The standard value ex factory is 2 bar.

i

Note!

Use a blow tube for the used type of printer.

A number of holes in blowing tube is covered by plastic rings. It is necessary remove so many rings that the

supporting air can reach whole label width.

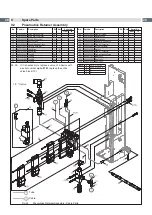

3

5

1

4

5

2

3

Fig. 13

Adjust the blow tube

The blow tube (3) for the supporting air can be rotated around its axis. That way the direction of the supporting air can

be optimized.

1. Loosen screw (1).

2. Put in the blow tube (3) into the tube adapter A (2).

Turn the blow tube (3) in that direction, that the air current supports the sucking of the label from the dispense

edge (5) by the pad (4).

- For small labels direct the air current to the dispense edge (4) of the printer.

- For larger labels direct the air current away from the dispense edge (4) .

Use the graduation to orientation.

3. Tighten screw (1).

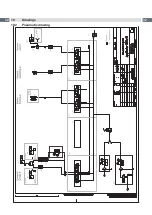

support air

vacuum

1

Fig. 14

Throttle valve "support air"

Adjust with the valve "support air" (1) the supporting air to blow the label against the pad.

To increase the supporting air turn counterclockwise the screw at the valve (1).