Page 14 of 38

GB

INSTRUCTION, USE AND

MAINTENANCE MANUAL

A

B

C

D

E

G2

G1

H

I

M

L

F1

F

F2

G

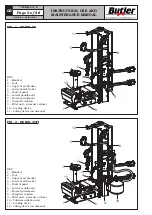

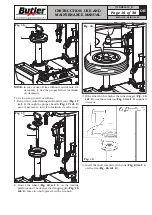

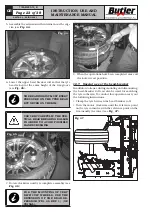

11.1 Control device (see Fig. 14)

The control device consists of a panel with integrated

keys and push buttons.

•

• Handle “

H

”

: through a thrust and return move-

ment and together with “

I

” unlocking push button it

enables the tool setting on the wheel diameter.

•

• Handle “

L

”

: through a thrust and return move-

ment and together with “

M

” unlocking push button

it enables the bead breaker rolls setting on the wheel

diameter.

•

Unlocking push button “

I

”

pushed before handle “

H

”

for tool positioning. Releasing the push button, the

tool locks itself into the set position.

•

Unlocking push button “

M

”

pushed before handle “

L

”

for bead breakers positioning. Releasing the push

button, the rolls lock into the set position.

ATTENTION: “

I

” and “

M

” push buttons must be

pressed before operating the corresponding “

H

” and

“

L

”

handles; otherwise, the levers do not allow any

movement.

Panel

C

consists of:

• Push button “

A

”, with a maintained action position.

When pressed, it controls the tool vertical downwards

translation.

• Push button “

B

”, with a maintained action position.

When pressed, it controls the tool vertical upwards

translation.

Fig. 14

11.0 CONTROLS

• Push button “

D

” has a maintained action position

and when it is pressed it controls the rotation, and,

at the same time, the introduction of the upper bead

breaker in the rim.

• Push button “

E

” has a maintained action position

and when it is pressed it controls the rotation, and,

at the same time, the introduction of the lower bead

breaker in the rim.

• Push buttons “

F

” have a maintained action posi-

tion and they control the vertical translation of the

upper bead breaker roll. When pressed in its lower

part (F2), it operates the downwards translation.

When pressed in its upper part (F1), it operates the

upwards translation. When the push button (F1) is

pressed, the release of the upper bead breaker roll

is also operated, if it has been previously introduced

with push button (D).

• Push buttons “

G

” have a maintained action position

and they control the vertical translation of the lower

bead breaker roll. When pressed in its lower part (G2),

it operates the downwards translation. When the push

button (G2) is pressed, the release of the lower bead

breaker roll is also operated, if it has been previously

introduced with push button (E). When pressed in its

upper part (G1), it operates the upwards translation.

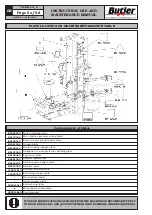

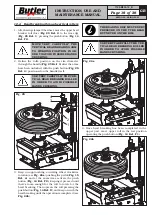

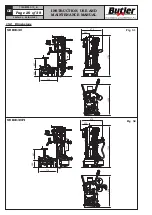

11.2 Pedalboard (see Fig. 15)

“Pedal A”

has two maintained action operative posi-

tions. When it is pushed downwards it controls man-

drel motor clockwise rotary movement. When the pedal

is lifted upwards it operates the opposite movement.

NOTE:

The mandrel unit speed can be continuously

adjusted up to the maximum speed through

a progressive pressure on the pedal, only in

clockwise direction.

“Pedal B”

has a different function according to the the

version present on the machine.

Version with inflation with pressure gauge

The inflation pedal in this version has only one fun-

ction. A continuous pressure supplies air at a control-

led pressure (max 4 ± 0,2 bar 58 PSI).

DO NOT CHANGE THE SET OPE-

RATING PRESSURE VALUE BY ME-

ANS OF THE MAXIMUM PRESSURE

VALVES. THE MANUFACTURER

SHALL NOT BE RESPONSIBLE

FOR INJURY OR DAMAGE ARISING

FROM UNAUTHORISED CHANGES.

Version with tubeless inflation

The inflation pedal has two functions. The supply of

air at a controlled pressure as in the previous version,

and a second function of a jet of air from the inflation

nozzle to assist the beading in of the tyre.

SEIDO.30 - SEIDO.30FI

7105-M005-10_B