Page 13 of 38

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

2

3

7

4

4

43" 41"

45"

5

1

3

5

3

5

6

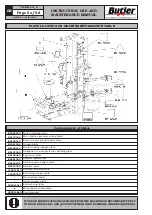

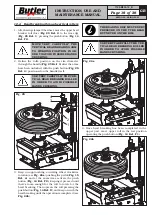

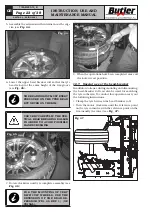

The column is moved by unloosing the fixing screws of

the base (

Fig. 12 ref. A

) to the column (

Fig. 12 ref. B

)

and by sliding the base (

Fig. 12 ref. A

) itself into the

proper slots until the required measure.

MAKE SURE THAT THE TYRE-

CHANGER COLUMN IS STABLE:

USE A CABLE HELD BY A HOIST

AND HOOK THE CABLE TO THE

COLUMN ITSELF

(

FIG. 13 REF. 7

)

.

1. Remove the lateral guard (

Fig. 13 ref. 1-2

) of the

machine.

2. Unscrew the screws (

Fig. 13 ref. 3

) and the nuts

near the central slots (

Fig. 13 ref. 4

) paying atten-

tion not to remove the nuts from the proper screws.

3. Remove the six remaining screws (

Fig. 13 ref. 5

).

4. Move the base (

Fig. 13 ref. 6

) into the required

position (to 43” or 45”) and if necessary, use a lifting

device (

Fig. 13 ref. 7

).

5. Lock the base three screws (

Fig. 13 ref. 3

) with a

couple of 80 Nm.

6. Place six screws (

Fig. 13 ref. 5

) previously remo-

ved and lock them on the bases side with a couple

of 80 Nm.

7. Assemble again the lateral guards (

Fig. 13 ref. 1-2

)

of the machine.

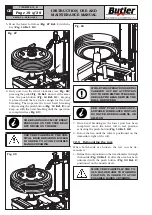

NOTE:

after the assembly, check the correct position

of the tools. Lock the rim on the mandrel cen-

tre. With the bead breaker arm, check that the

distance between the roll and the rim edges

(upper and lower) is the same. Repeat all the

procedures starting from point 1 if the distance

is not the same.

Fig. 13

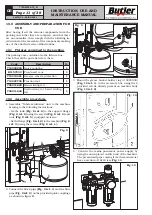

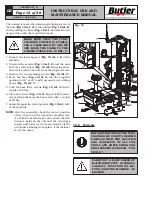

10.5 Controls

BEFORE STARTING UP THE TYRE-

CHANGER, BE SURE TO BECOME

FAMILIAR WITH THE LOCATION

AND OPERATION OF ALL CON-

TROLS AND CHECK THEIR PRO-

PER OPERATION (SEE PAR. “CON-

TROLS”).

CARRY OUT A DAILY CHECK OF

MAINTAINED-TYPE CONTROLS

CORRECT FUNCTIONING, BE-

FORE STARTING MACHINE OP-

ERATION.

SEIDO.30 - SEIDO.30FI

7105-M005-10_B