INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 29 of 68

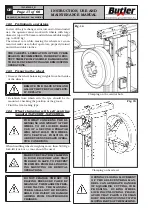

• Mount the accessory (as shown in

Fig. 39

) and posi-

tion the beading disc on rim edge (see

Fig. 39

).

Fig. 39

• Turn the mandrel and smear the entire bead seat

of the rim with lubricant. While doing this, jerk the

beading disc forward until the first bead is removed

(as these wheels feature inner tubes, carry out the

operation carefully, paying special attention to when

the bead dislodges, trying to stop disc advancement

immediately to avoid compromising the integrity of

the inner tube and valve).

• Bring the roll holder arm in “out of work” position

(

Fig. 18 pos. 1

); by operating on the handle control

position the roll holder arm on the external side of

the wheel then bring it back into “working” position

(

Fig. 17 pos. 1

) and lock it with the special safety pin.

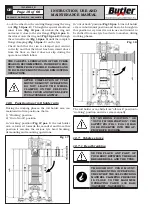

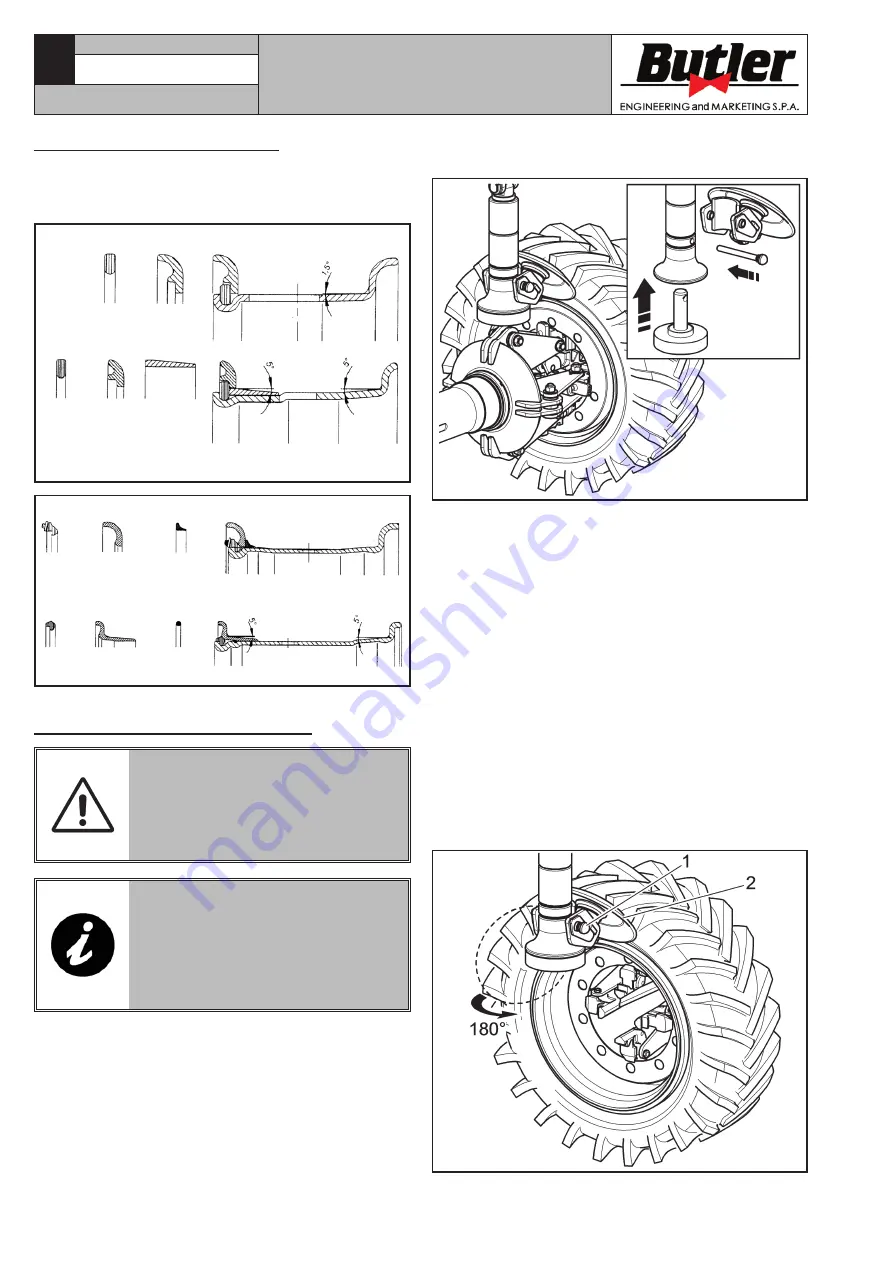

• Remove the pin (

Fig. 40 pos. 1

), turn the beading

disc (

Fig. 40 pos. 2

) with 180° rotation and lock it

again with the pin (

Fig. 40 pos. 1

) in order to be

able to bring the beading disc itself in contact with

the external side of the tyre (see

Fig. 40

).

Fig. 40

7503-M002-6_B

NAV26HW - NAV26HW.S - NAV26HW.ST

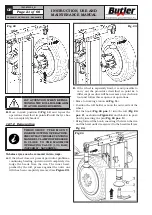

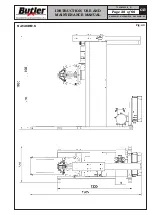

12.9 Wheels with bead wire

As an example

Fig. 37

and

38

illustrate sections and

compositions of types of wheels with bead wire cur-

rently being sold.

Fig. 37

Lock

ring

Lock

ring

Non split

side ring

Non split

side ring

Tapered

bead seat

ring

Three-piece flat base rim and pertinent rings for

tubed tyres and SOLID tyres

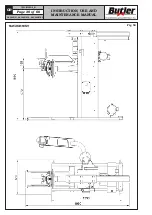

Four-piece 5” tapered bead seat rim and perti-

nent rings for tubed and SOLID tyres

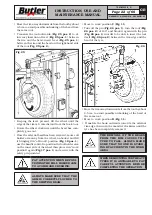

Fig. 38

Lock

ring

Lock

ring

Non split

ring

Non split

ring

Rubber seal-

ing ring

O-sealing

ring

12.9.1 Beading and demounting

NEVER STAND IN FRONT OF THE

WHEEL WHILE THE INFLATION

RING IS BEING EXTRACTED FROM

THE BEAD WIRE, SINCE IT MAY BE

EJECTED VIOLENTLY, CAUSING

SERIOUS INJURIES OR WOUNDS.

THROUGHOUT TYRE MOUNT-

ING/DEMOUNTING OPERATIONS,

CHECK THAT THE SELF-CENTRING

MANDREL CLAMPING PRESSURE

IS CLOSE TO THE MAXIMUM

OPERATING VALUE (130 BAR)

(NAV26HW - NAV26HW.S).

• Mount the wheel on the mandrel as described in

“WHEEL CLAMPING” and make sure it is deflated.

• Move to work position

C

(

Fig. 11

) with G108A22

fixture (optional).

• Place the roll holder arm in “working position” (

Fig.

17 pos. 1

) in the tyre inner side, and make sure it

is locked by the provided safety stop (

Fig. 1, 2

and

3 pos. 12

).