INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 14 of 68

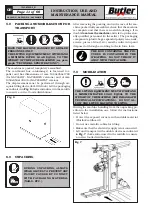

10.0 WORKING ENVIRONMENT CONDI-

TIONS

The machine must be operated under proper condi-

tions as follows:

• temperature: 0° + 55° C

• relative humidity 30 - 95% (dew-free)

atmospheric pressure: 860 - 1060 hPa (mbar).

The use of the machine in ambient conditions other

than those specified above is only allowed after prior

agreement with and approval of the manufacturer.

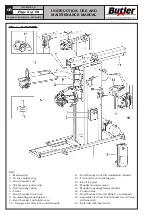

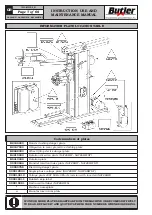

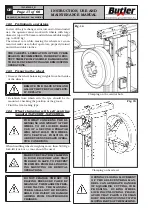

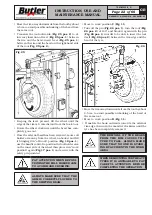

10.1 Working position

In

Fig. 11

it's possible to define working positions

A,

B, C

which will be referred to in the description of

machine operative phases.

Positions

A

and

B

must be considered as main posi-

tions for tyre mounting and demounting and for wheel

clamping on the mandrel, while positions

A

and

C

are

the best positions to follow tyre bead breaking and

demounting operations.

Working in these positions allows better precision and

speed during operating phases as well as greater safety

for the operator.

10.2 Working area

Fig. 11

INSTALL THE MACHINE INDOORS OR IN A

ROOFED AREA. PLACE OF INSTALLATION

MUST BE DRY, ADEQUATELY LIT AND IN

COMPLIANCE WITH APPLICABLE SAFETY

REGULATIONS.

7503-M002-6_B

NAV26HW - NAV26HW.S - NAV26HW.ST

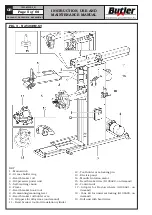

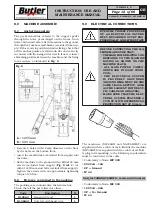

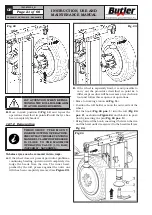

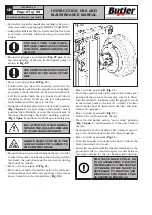

Then horizontally or vertically move the lever (

Fig. 13

pos. E

): the red LED (

Fig. 13 pos. B

) will flash.

Wait a few seconds for the green LED to turn on (

Fig.

13 pos. A

) and then release the lever (

Fig. 13 pos. H

).

In the end, the green LED (

Fig. 13 pos. A

) flashes to

indicate that the machine is ready for operation.

WHEN A CONTROL IS OPERATED,

THE GREEN LED (FIG. 13 POS.

A) LIGHT IS FIXED: IT FLASHES

AGAIN WHEN IT IS RELEASED.

If during the operations the red LED (

Fig. 13 pos. B

)

and the green LED (

Fig. 13 pos. A

) turn on at the same

time, charge the control batteries with the provided

socket for battery charger, located on the control side

(

Fig. 13 pos. G

).

The machine is equipped with a device for the interrup-

tion of the communication between the control and the

electrical panel, when more than 6 hours have passed

after the last executed control. In this case, just repeat

the turning on operations described in the “Electrical

checks” chapter.

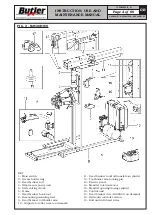

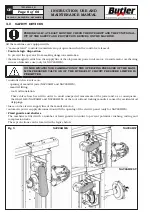

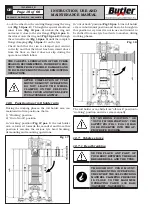

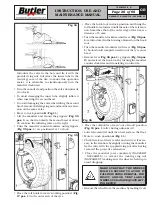

NAV26HW - NAV26HW.ST

KEY

A - Main switch

B - Direction rotation of oil-pressure power unit

motor

C - Selector 1-0-2 self-centring chuck speed con-

trol (only for VARGNAV26HWD - version with

inverter)

Fig. 10

ONCE THE ASSEMBLY OPERA-

TIONS HAVE BEEN ENDED, CHECK

ALL MACHINE FUNCTIONS.