4. MAINTENANCE

DAILY CHECKS

Check all hardware daily before operation.

Tighten hardware to torque values as specified in

the Torque Chart, page 43 unless otherwise speci-

fied.

With the engine off and the bucket on the ground,

inspect all hoses for cuts or wear. Check for signs of

leaks and make sure all fittings are tight.

CAUTION

ESCAPING HYDRAULIC FLUID UNDER

PRESSURE CAN HAVE SUFFICIENT

FORCE TO PENETRATE SKIN, CAUSING

SERIOUS PERSONAL INJURY. BEFORE

DISCONNECTING LINES, BE SURE TO

RELIEVE ALL PRESSURE.

BEFORE APPLYING PRESSURE TO SYS-

TEM, BE SURE ALL CONNECTIONS ARE

TIGHT AND THAT LINES, TUBES, AND

HOSES ARE NOT DAMAGED.

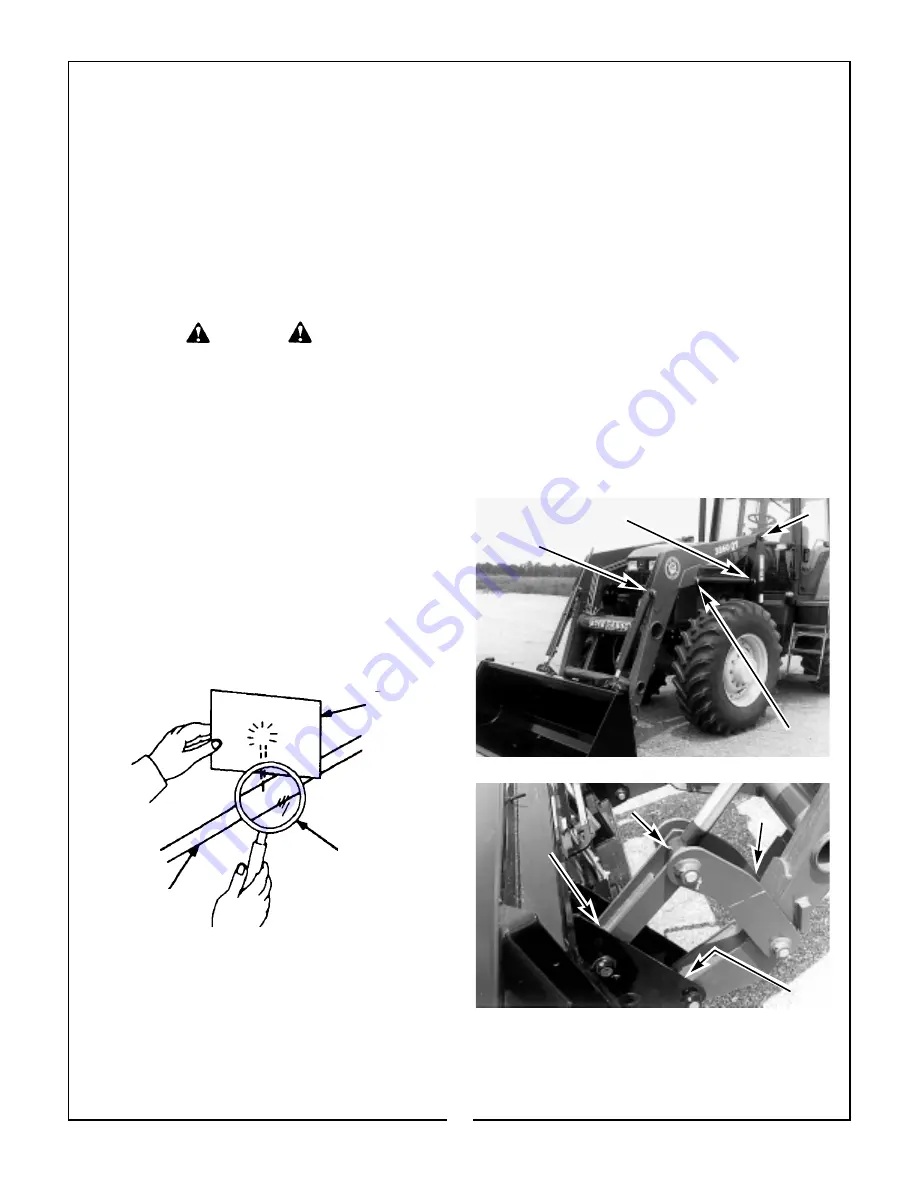

FLUID ESCAPING FROM A VERY SMALL

HOLE CAN BE ALMOST INVISIBLE. USE A

PIECE OF CARDBOARD OR WOOD,

RATHER THAN HANDS, TO SEARCH FOR

SUSPECTED LEAKS.

IF INJURED BY ESCAPING FLUID, SEE A

DOCTOR AT ONCE. SERIOUS INFECTION

OR REACTION CAN DEVELOP IF PROPER

MEDICAL TREATMENT IS NOT ADMINIS-

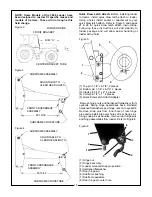

TERED IMMEDIATELY. REFER TO FIGURE 1.

Figure 1

2

3

1

(1) Hydraulic line.

(2) Cardboard.

(3) Magnifying glass.

Service your loader at the intervals and locations as

specified. When you service your loader, use only

high quality lubricants. The engine hour meter on the

tractor shows the amount of hours the engine has

worked. Use the hour meter to service your loader at

the correct time periods.

IMPORTANT: Lower the loader boom to the

ground and relieve pressure in loader hydraulic

lines prior to doing any service or maintenance

operations on the tractor or loader.

Check the tractor hydraulic fluid level as speci-

fied in the tractor Operator Manual.

NOTE: When checking hydraulic system fluid

level, the loader boom must be on the ground

with the bucket or attachment resting flat on a

level surface.

LOADER LUBRICATION

Position bucket and/or attachment level with ground,

lower loader boom to ground, and relieve all

hydraulic pressure before lubricating. Refer to

Figures 2 & 3.

There are 16 grease fittings on the Model 3860

Loader, one at each pivot point. Lubricate pivots as

specified.

Figure 2

(1) Lubricate these 8 pivot points every 10 hours of

operation.

(2) Lubricate these 8 pivot points every 5 hours of

operation.

Figure 3

1

1

1

1

2

2

2

2

15