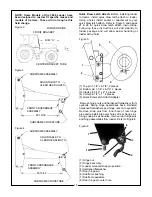

Using a hoist to support the loader frame, align the

subframe crosstube with the front bracket. Refer to

Figure 7 and Figures 2, 3, & 4, page 10.

CAUTION

LIFT AND SUPPORT ALL LOADER COMPO-

NENTS SAFELY.

2

1

(1) Subframe Crosstube.

(2) Front Bracket.

Slowly drive the tractor forward until the subframe

crosstube is seated into the front bracket. Using

hoist, lower the front end loader until the subframe

assembly is seated on center bracket tubes. Refer to

Figures 2, 3, & 4, page 10.

Using snap pins as handles, reinstall rear hinge pins

and hinge assemblies. Remove snap pins from outer

holes of rear hinge pins and reinstall into inner holes.

Secure rear hinge pins to subframe bushings in

loader mounted position as shown in Figure 8.

Remove hinge nuts and hardened flatwashers from

eyebolts. Swing hinge assemblies forward. Secure

by locking hinge assemblies into position using hard-

ened flatwashers and hinge nuts. Torque hinge nuts

to 200 ft. lb. Refer to Figures 8 & 9.

FIGURE 8

7

2

4

1

6

3

5

8

9

7

3

Figure 9

Figure 7

(1) Hinge nut.

(2) Hinge assembly.

(3) Snap pin in loader mounted position.

(4) Hardened flatwasher.

(5) Rear hinge pin.

(6) Subframe bushing.

(7) Subframe pedestal.

(8) Center mounting bracket tubes.

(9) Rear hinge pin outer hole.

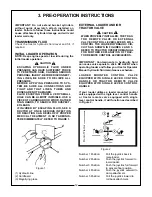

TORQUE IDENTIFICATION

Torque all mounting kit and loader hardware as

specified.

(A) Identify hardware size and grade.

(B) Refer to Torque Chart, page 43 and find correct

torque for your hardware size and grade.

(C) Torque hardware to this specification unless

otherwise specified.

IMPORTANT: Make sure that all front bracket to

tractor hardware and loader subframe to front

crossbrace assembly hardware has been

torqued properly before operating loader. Refer

to Figure 10.

Loader Subframe

Loader Subframe to

Front Crossbrace

Asembly (3 each side)

Loader Subframe

Front Crossbrace Assy.

Front Bracket to Tractor Bolts

(Quantity varies with Bracket Design

Figure 10

11