Product Description

Use

The vacuum pump is intended for

–

the suction

of

–

air and other dry, non-aggressive, non-toxic and non-explosive

gases

Conveying media with a lower or higher density than air leads to an in-

creased thermal and/or mechanical load on the vacuum pump and is

permissible only after prior consultation with Busch.

In case the vacuum pump is equipped with a gas ballast (optional) wa-

ter vapour within the gas flow can be tolerated within certain limits

(

page 8: Conveying Condensable Vapours). The conveyance of

other vapours shall be agreed upon with Busch.

The vacuum pump is intended for the placement in a non-potentially

explosive environment.

Version with oil return line to the suction connection (RC 0006 C/E):

The vacuum pump is thermally suitable for continuous operation

(100 percent duty).

Version with oil return valve (RB 0006 C/E):

The vacuum pump is thermally suitable for continuous operation (ob-

serve the notes with regard to the oil recirculation:

page 3: Oil Cir-

culation;

page 8: Oil Return).

The vacuum pump is ultimate pressure proof.

Principle of Operation

The vacuum pump works on the rotating vane principle.

A circular rotor is positioned centrically on the shaft of the vacuum

pump (i.e. drive motor shaft).

The rotor rotates in an also circular, fixed cylinder, the centreline of

which is offset from the centreline of the rotor such that the rotor and

the inner wall of the cylinder almost touch along a line. Vanes, sliding

in slots in the rotor, separate the space between the rotor and the cyl-

inder into chambers. At any time gas is sucked in and at almost any

time ejected. Therefore the vacuum pump works almost pulsation free.

In order to avoid the suction of solids, the vacuum pump is equipped

with a screen in the suction connection.

In order to avoid reverse rotation after switching off, the vacuum

pump is equipped with a non-return valve.

Note

: This valve shall not be used as a non-return valve or shut-off

valve to the vacuum system and is no reliable means to prevent suction

of oil into the vacuum system while the vacuum pump is shut down.

In case the vacuum pump is equipped with a gas ballast (optional):

Through the gas ballast a small amount of ambient air is sucked into

the pump chamber and compressed together with the process gas. This

counteracts the accumulation of condensates from the process gas in-

side the vacuum pump (

page 8: Conveying Condensable Vapours).

The gas ballast line is equipped with a paper filter.

Oil Circulation

The vacuum pump requires oil to seal the gaps, to lubricate the vanes

and to carry away compression heat.

The oil reservoir is located on the pressure side of the vacuum pump

(i.e. high pressure) at the bottom of the bottom chamber of the oil

separator (f).

The feed openings are located on the suction side of the vacuum pump

(i.e. low pressure).

Forced by the pressure difference between pressure side and suction

side oil is being drawn from the oil separator (f) through the oil supply

lines and injected on the suction side.

Together with the sucked gas the injected oil gets conveyed through

the vacuum pump and ejected into the oil separator (f) as oil mist. Oil

that separates before the exhaust filter accumulates at the bottom of

the bottom chamber of the oil separator (f).

Oil that is separated by the exhaust filter accumulates at the bottom of

the upper chamber of the oil separator (f).

The flow resistance of the exhaust filters causes the inside of the ex-

haust filters (which is connected to the bottom chamber of the oil sep-

arator) to be on a higher pressure level than the outside of the exhaust

filters (i.e. the upper chamber of the oil separator). Because of the

higher pressure in the bottom chamber it is not possible to let oil that

drips off the exhaust filters simply flow down to the bottom chamber.

Version with oil return line to the suction connection (RC 0006 C/E):

Therefore the oil that accumulates in the upper chamber is sucked

through the oil return line right to the suction connection.

Version with oil return valve (RB 0006 C/E):

At continuous operation this would cause the entire supply of oil to ac-

cumulate at the bottom of the upper chamber, expel oil droplets

through the gas discharge/pressure connection and let the vacuum

pump run dry. Therefore the vacuum pump must be shut down at the

latest after 0.5 hours of continuous operation, depending on the oper-

ating conditions even after a shorter period, for at least approx. 5 min-

utes (

page 7: Operation Notes). After turning off the vacuum pump

the pressure difference between the inside and the outside of the ex-

haust filter(s) collapses, hence the two chambers of the oil separator

assume an equal pressure level, the oil return valve between the two

chambers opens and the accumulated oil in the upper chamber can run

down to the bottom chamber.

Cooling

The vacuum pump is cooled by

–

radiation of heat from the surface of the vacuum pump incl. oil

separator (f)

RB/RC 0006 C/E

Product Description

0870152229

page 3

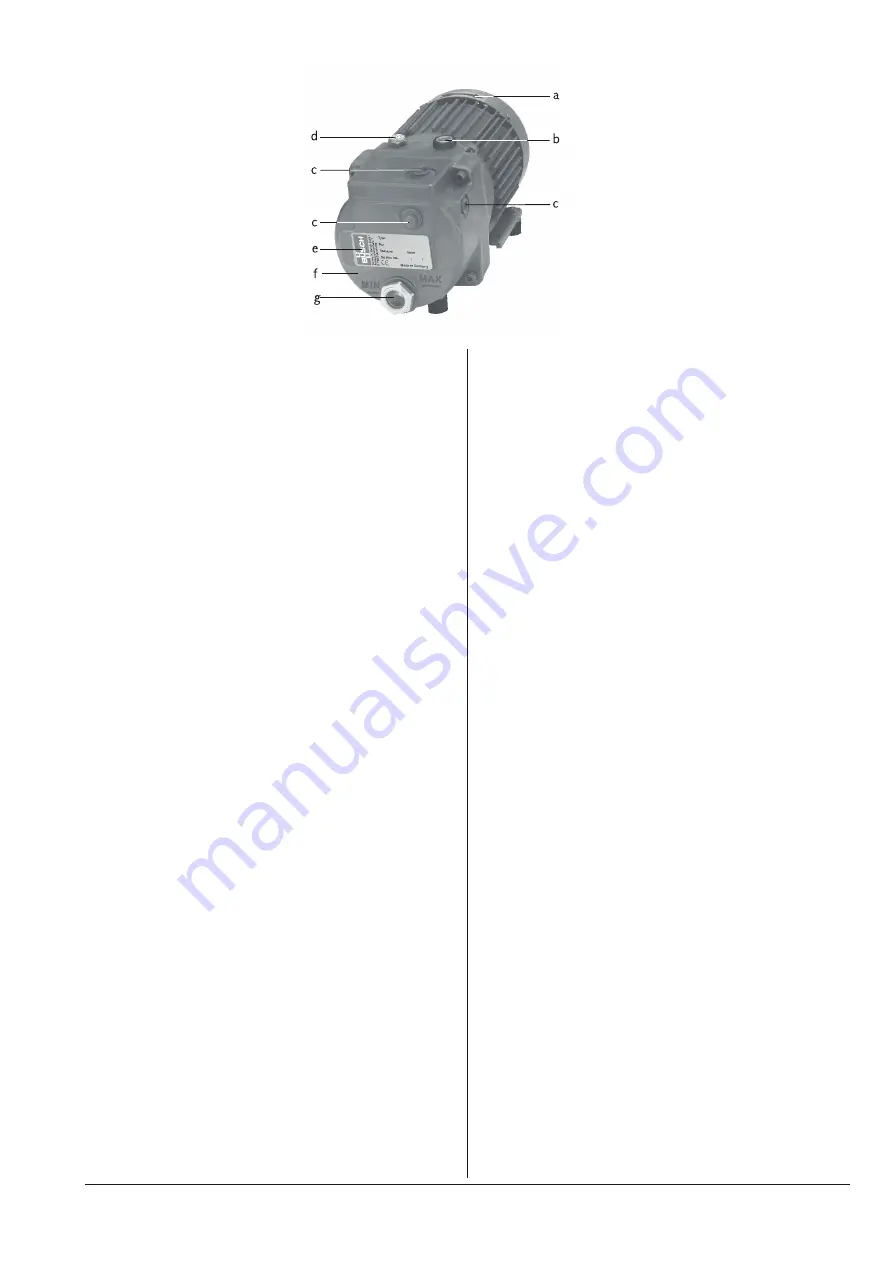

a

Directional arrow

b

Oil fill plug

c

Suction connections

d

Gas discharge

e

Nameplate

f

Oil separator

g

Oil sight glass

Содержание R5 RB 0006 C

Страница 20: ......