Maintenance | 7

0870219588_NS0600C_WCV_Ex_-0000_IM_en

25 / 40

• Turn on the barrier gas supply.

• Adjust the barrier gas pressure and volume flow.

• Switch on the machine.

• Make sure that the maximum permissible number of starts does not exceed 2 starts

per hour. Those starts should be spread within the hour.

• Make sure that the operating conditions comply with the

• After a few minutes of operation, perform an

.

• After a few minutes of operation, perform a

Cooling Liquid Level Inspection [

.

As soon as the machine is operated under normal operating conditions:

• Measure the motor current and record it as reference for future maintenance and

troubleshooting work.

6.1 Conveying Condensable Vapours

The machine, equipped either with a gas ballast valve or a dilution gas system, is suitable

for the conveyance of condensable vapours within the gas flow.

If condensable vapours are to be conveyed:

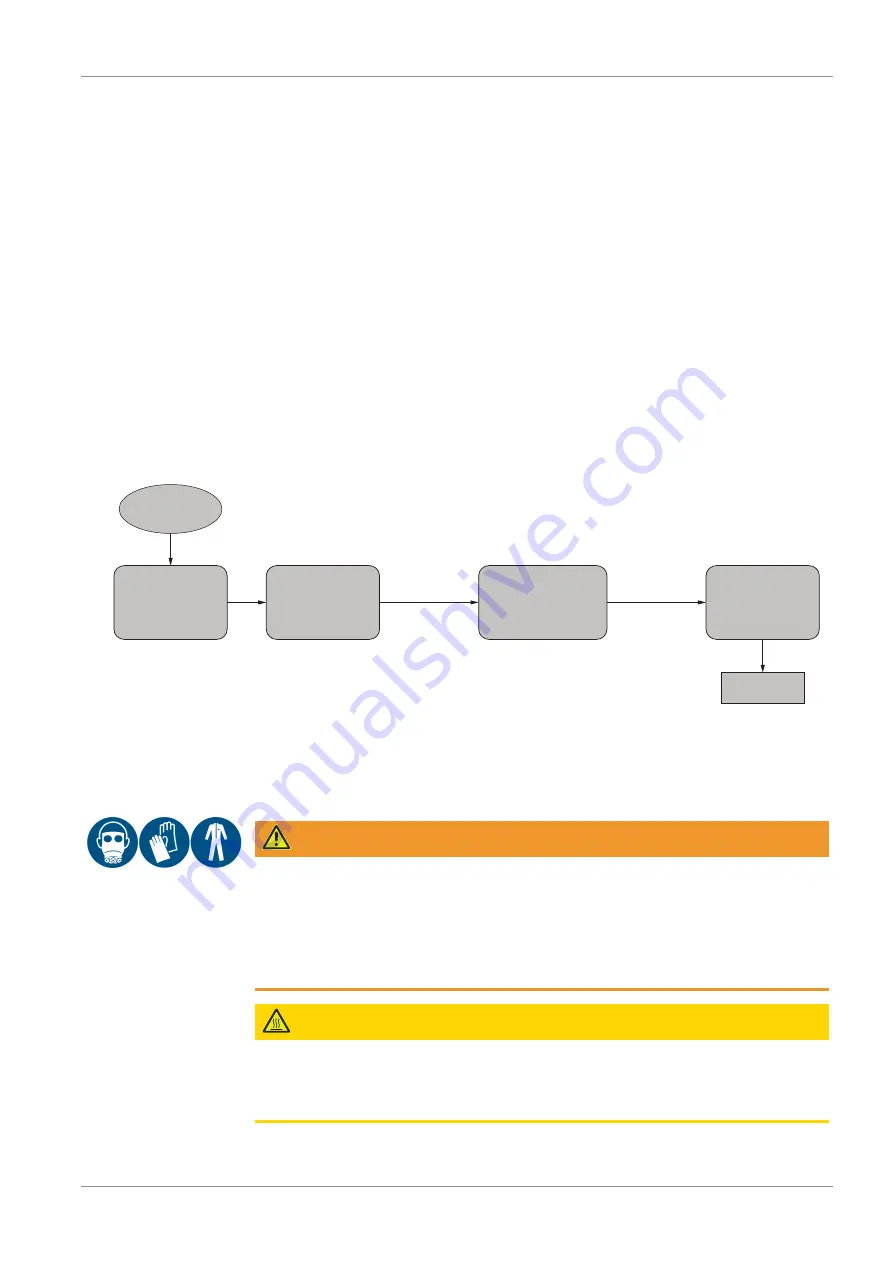

START

Open the gas ballast

valve* or the

dilution gas sytem*

(solenoid valve)

Warm up the

machine

30 minutes

30 minutes

• Open the inlet

valve

• Perform the process

• Close the inlet

valve

Close the gas ballast

valve*

or

the dilution gas

system*

END

* optional accessories

• Continuously drain condensate from the condensate drain plug (CD) of the silencer

(SI) (Optional).

7

Maintenance

WARNING

Machines contaminated with hazardous material.

Risk of poisoning!

Risk of infection!

If the machine is contaminated with hazardous material:

• Wear appropriate personal protective equipment.

CAUTION

Hot surface.

Risk of burns!

• Prior to any action requiring touching the machine, let the machine cool down first.

Содержание COBRA NS 0070-0600 C

Страница 38: ...Note ...

Страница 39: ...Note ...