MM3156A DRUM SANDER

17

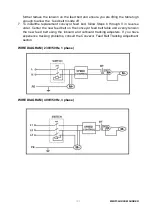

approximately 1/4 turn increments and evaluate the results. RE-adjust as

necessary until the proper tracking solution is found.

HELPFUL HINT

Tighten the side opposite the desired tracking direction. For example, tighten the

right side tracking adjustment to make the conveyor feed belt track left.

OPERATING INSTRUCTIONS

WARNING:

Never put your fingers into port or under drum cover.

CAUTION:

To avoid damage to your Durm Sander, adequate dust collection must be

must be used during sanding operations. A 2-

1/2” port is included in the sanding drum

dust cover for connecting dust collection unit/hose to your Wide Drum Sander.

DRUM HEIGHT CONTROL

The height of the drum is raised by turning the height control knob (refer to Figure 2) in a

clockwise direction. To lower the drum, turn the height control knob in the

counter-clockise direction. The depth of the move

ment is approximately 1/64” per 1/4

turn in either direction.

One complete turn is 1/16”. Depth settings can be measured

using the depth indicator scale located on the right side of the drum support frame.

NOTE: Depth settings used during surface sanding of stock are adjusted by

considering several variables.The hardness of the material, the width of the

material being surfaced, and the feed rate selected are all considered when

determing the amount of material to be removed on each pass. Never remove

more

than 1/32”of material in one pass. The variable feed rate is set to prevent

burning and provide a smooth sanded surface on different types and widths of

materials.

As a general rule,1/4 turn or 1/64” or less is recommended stock

removal for coarser grits and softer woods, while 1/8

of a turn or 1/128” may be

more desirable with harder woods and/or finer grits if abrasives. When selecting

the rate of feed for the material being surfaced, the wider the material, the slower

the feed rate to be set. Similary, the harder the wood, the slower the feed rate.

Some experimenting and practice will be required to become familiar with the sanding

performance of your Wide Drum Sander. While performing a surfacing operation with

your Wide Drum Sander closely parallels the wide surface preparation of a planer, a

planer is much more capable of making deeper passes due to its characteristic knives,