www.bullard.com

9

Inspection Cleaning and Stor

age

RT Series Respirator Hood

User Manual for use with supplied air respirators

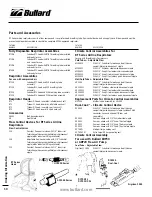

Breathing Tube

Inspection

Inspect the breathing tube for tears, cracks, holes, or excessive wear that

might reduce the degree of protection originally provided. If any signs of ex-

cessive wear are present, replace the breathing tube immediately or remove

the respirator from service.

Cleaning

To clean the breathing tube, hand-sponge with warm water and mild deter-

gent, being careful not to get water inside. Rinse and air-dry. After cleaning,

once again carefully inspect breathing tube for signs of damage.

Flow Control Valve/

Climate Control Device

Inspection

Be sure the hose thread is screwed tightly into the breathing tube so no air

can escape during use. Check the adjustment knob on the flow control device

for cracks and other damage.

Cleaning

To clean, hand-sponge with warm water and mild detergent, being careful

not to get water inside. After cleaning, once again carefully inspect breathing

tube for signs of damage. If any signs of excessive wear are present, replace

the flow control valve/climate control device or remove the respirator from

service.

Air Supply Hoses

Inspection

Air supply hose(s) should be inspected closely for abrasions, corrosion, cuts,

cracks and blistering. Be sure the hose fittings are crimped tightly to the hose

so that no air can escape. Make sure the hose has not been kinked or crushed

by any equipment that may have rolled over it.

If any of the above signs are present or any other signs of excessive wear

are detected, replace the hose(s) immediately or remove the respirator from

service.

Cleaning

The air supply hose(s) should be hand-sponged with warm water and mild

detergent, rinsed and air dried. Do not get water inside the air supply hose.

After cleaning, once again carefully inspect air supply hose(s) for signs of

damage.

Storage

After reusable respirator components have been cleaned and inspected, place

them in a plastic bag or an airtight container.

Store the respirator and parts where they will be protected from contamina-

tion, distortion and damage from elements such as dust, direct sunlight, heat,

extreme cold, excessive moisture and harmful chemicals. Five-year maximum

shelf life.

WARNING

Do not cut or remove the foam that is inside the RT Series Airline

Respirator breathing tube. The foam helps reduce the noise level of

the incoming air supply. It does not filter or purify your breathing air.

NIOSH has approved this respirator with the foam in place. Failure to

follow these instructions may result in minor or moderate injury and/or

equipment damage.

WARNING

Only use air supply hoses that are NIOSH approved for use with the RT

Series respirator. Other hoses could reduce airflow and protection, and

expose the wearer to life-threatening conditions. Failure to follow these

instructions could result in death or serious injury.