What, if...

24

4.6.1

Interruptions in work/End of shift

1. Before switching off the device, set it down with the nozzle in a paraffin oil bath (a

suitable stainless steel pot is included in the delivery).

2. Before resuming operation, allow the cartridge to heat thoroughly for approx. 20 mi-

nutes.

3. Take the nozzle out of the paraffin oil bath. Wipe off the nozzle with a cloth.

4. Discharge approx. 1 cm³ hot melt material.

The device is now ready for operation again.

4.6.2

Longer shutdown times

1. Remove the cartridge (see section 4.6).

2. Insert a pre-heated cartridge with BÜHNEN cleaner 71082.

3. Discharge about half of the cleaner to rinse out the device.

4. Switch off the device.

5. Before resuming operation, allow the device to heat thoroughly for approx. 20 mi-

nutes.

6. Discharge the rest of the cleaner.

The device is now ready for use again.

5

What, if...

This Section summarises the status and error messages and provides help in eliminating

errors.

If malfunctions occur please check first

• hat the power supply and

• compressed-air supply are functioning correctly, and

• whether there is mechanical damage to the device or supply lines

(power supply, compressed air).

If you find any mechanical damage, the device may in no circumstances be started up

again. Have it checked and repaired by a qualified service agent.

5.1

Status and error messages in the display

Indication

Cause

Action

Decimal point on left flashes Warm-up phase active

The warm-up phase is ended when a

temperature 2°C short of the set working

temperature has been reached.

Decimal point on right is lit

Setpoint lowering active

See parameters P1 and P2 (Section 3.3.2)

ERR

Permitted maximum tempera-

ture of 260 °C exceeded

Allow to cool down

F1L

Sensor fault, short circuit

Have the device checked by a qualified

service agent.

F1H

Sensor fault, sensor breakage

Have the device checked by a qualified

service agent.

--

Keylock active

See parameter P19 (Section 3.3.2)

EP

Data loss in parameter memory The regulator must be replaced by a quali-

fied service agent.

GB

Содержание HB 700 KD

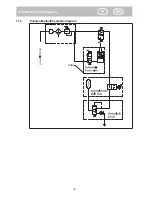

Страница 38: ...Anschlu pl ne Diagrams 38 11 2 Pneumatikplan Pneumatic diagram GB D...

Страница 39: ...Konformit tserkl rung 39...

Страница 40: ...Declaration of Conformity 40...