7

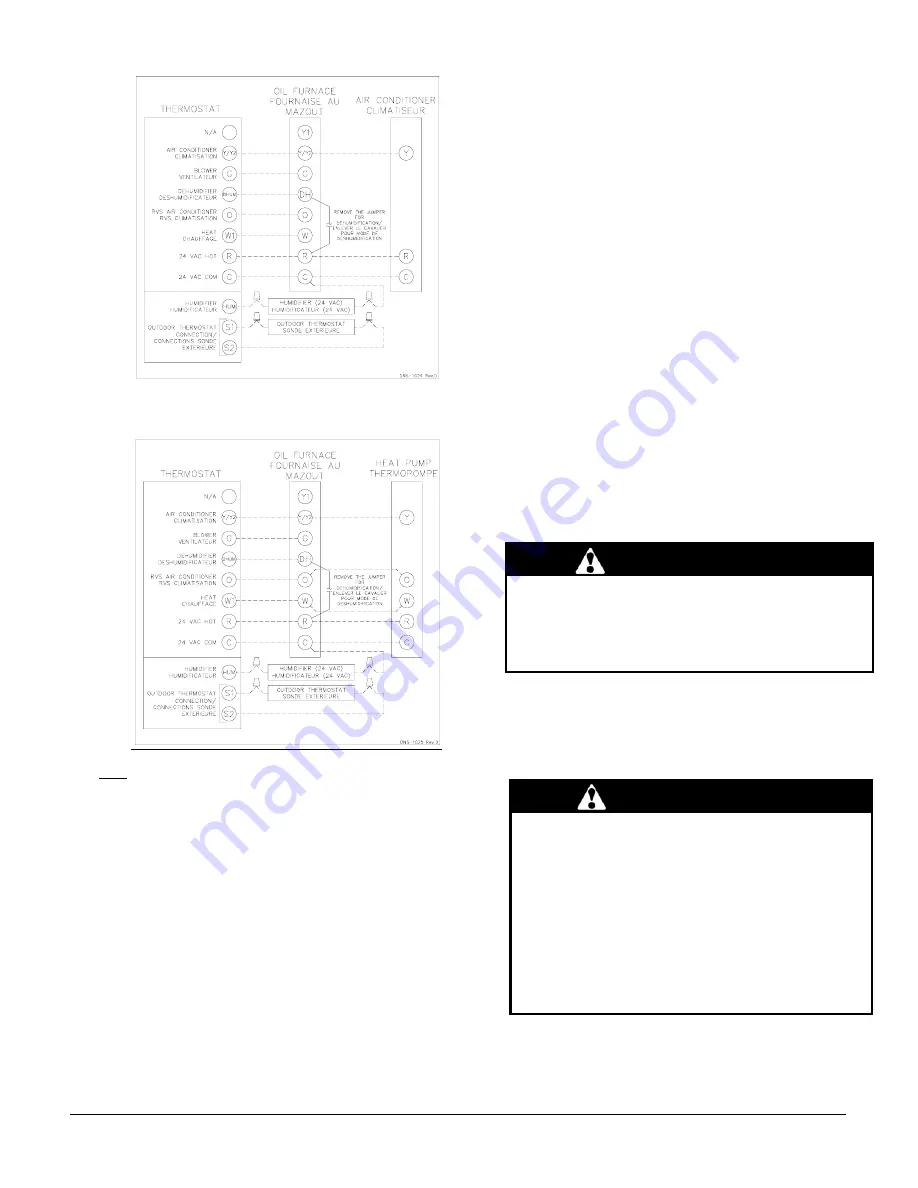

Figure 7: Thermostat wiring, heating and air cond. heat

pump with ECM v. speed motor

Note: On units with 2 stage cooling or heat pump, terminal Y1

must be used. When Y1 on the electronic control receives a 24

VAC signal, the air flow is reduced by 20%. Do not use

terminal Y1 with a single stage cooling or heat pump.

2.5 INSTALLATION

OF

THE

BURNER

Refer to the burner manufacturer’s instructions. Also, the

burner must be installed always in the same way

independently of the furnace orientation.

1. Position the mounting gasket between the mounting

flange and the burner mounting plate. Align the holes in

the burner mounting plate with the studs on the mounting

flange and bolt securely in place.

2. Remove the burner drawer assembly or the air tube

assembly;

3. Install the nozzle, refer to Technical Specifications Table

6;

4. Check the electrode settings;

5. Make the electrical connections;

6. Complete oil line connections.

2.5.1 Nozzles

The burner comes equipped with an appropriate nozzle.

However, if another size or a replacement nozzle is

required, use the manufacturer’s recommended spray

angle and type a shown in Table 6 and based on a pump

pressure of 100 psi.

Always select nozzle sizes by working back from the

desired flow rate at operating pressure and not the nozzle

marking.

2.5.2 Air and Turbulator Settings

Before starting the burner for the first time, adjust the air

and turbulator settings to those listed in this manual, Table

6. Once the burner becomes operational, final

adjustments will be required. Refer to section 3 of this

manual.

2.5.3 Post purge delay adjustment

The post purge delay on the oil-fired burners is factory set

to zero second. This delay is applicable for all installations

with chimney venting. For heating units installed with side

wall venting and a burner equipped with this feature, the

post purge delay must be set to 15 seconds. Refer to the

burner control instruction manual and markings for proper

adjustment of the post purge delay.

2.6 VENTING

WARNING

Poisonous carbon monoxide gas, fire and explosion

hazard.

Read and follow all instructions in this section.

Failure to properly vent this furnace can result in in

death, bodily injury and/or property damage.

To ensure the safe and proper functioning of an oil

furnace, it must always be connected to a flue with

sufficient draft or to an approved side-wall venting system.

In addition, it is strongly recommended to perform a

complete inspection of all the existing venting systems.

WARNING

Poisonous carbon monoxide gas hazard.

Never install a hand operated damper in the vent pipe.

However, any Underwriters Laboratories listed,

electrically operated automatic type vent damper may

be installed if desired. Be sure to follow the

instructions provided with vent damper. Also, read

and follow all instructions in this section of the

manual.

Failure to properly vent this furnace or other

appliances can result in death, bodily injury and/or

property damage.

Содержание OBM098

Страница 18: ...18 Figure 9 Furnace dimensions...

Страница 19: ...19 Figure 10 Wiring diagram 4 speed motor PSC...

Страница 20: ...20 Figure 11 Wiring diagram variable speed motor ECM...

Страница 21: ...21 COMPONENTS AND REPLACEMENT PARTS...

Страница 22: ...22 Figure 12 Parts list with 4 speed motor PSC B50064G...

Страница 24: ...24 Figure 13 Parts list with variable speed motor ECM B50074H...

Страница 44: ...19 Figure 9 Dimensions de la fournaise...

Страница 45: ...20 Figure 10 Diagramme lectrique moteur 4 vitesses PSC...

Страница 46: ...21 Figure 11 Diagramme lectrique moteur vitesse variable ECM...

Страница 47: ...22 COMPOSANTES ET PI CES DE REMPLACEMENT...

Страница 48: ...23 B50064G Figure 12 Liste de pi ces avec moteur 4 vitesses PSC...

Страница 50: ...25 B50074G Figure 13 Liste de pi ces avec moteur vitesse variable ECM...