158

POWERHEAD

CRANKSHAFT, PISTONS AND CAMSHAFT

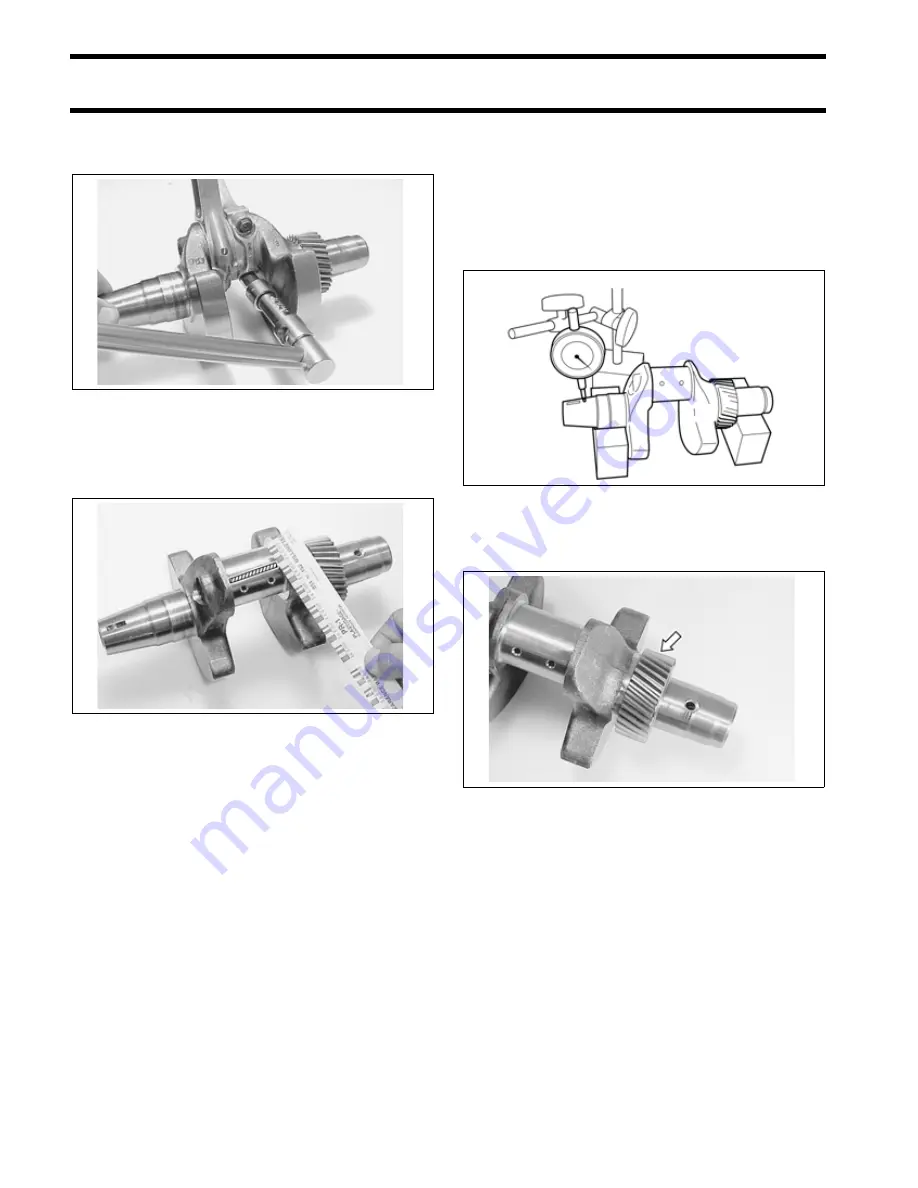

•

Apply engine oil to screws and tighten in two

steps to 102 in. lbs. (12 N·m).

•

Remove rods and caps from crankpin.

•

Measure the compressed Plastigage at its wid-

est point.

Connecting rod big end oil clearance:

•

Standard: 0.0008 to 0.0012 in. (0.020 to 0.030

mm).

•

Service limit: 0.0026 in. (0.065 mm)

If measurement exceeds service limit, replace

connecting rod and/or crankshaft.

Crankshaft

Measure crankshaft runout using “V” blocks and a

dial indicator. If measurement exceeds service

limit, replace crankshaft and/or crankcase.

Crankshaft runout:

•

Service limit: 0.002 in. (0.05 mm)

Inspect timing gear. Replace crankshaft if dam-

aged or worn.

Oil Seals and Bearings

Visually check the oil seals in the cylinder block

and bottom crankcase for cuts, nicks, excessive

wear or other damage.

Check main bearings for pitting and noisy or

rough operation.

005723

005724

005725

005726

Содержание Johnson BJ25E4SUC

Страница 1: ......

Страница 2: ......

Страница 66: ...64 MAINTENANCE NOTES NOTES Technician s Notes Related Documents Bulletins Instruction Sheets Other ...

Страница 104: ...102 IGNITION SYSTEM NOTES NOTES Technician s Notes Related Documents Bulletins Instruction Sheets Other ...

Страница 124: ...122 FUEL SYSTEM NOTES NOTES Technician s Notes Related Documents Bulletins Instruction Sheets Other ...

Страница 172: ...170 POWERHEAD NOTES NOTES Technician s Notes Related Documents Bulletins Instruction Sheets Other ...

Страница 238: ...S 2 ...

Страница 265: ......