44

WSW45

(Speeding up scanning-2)

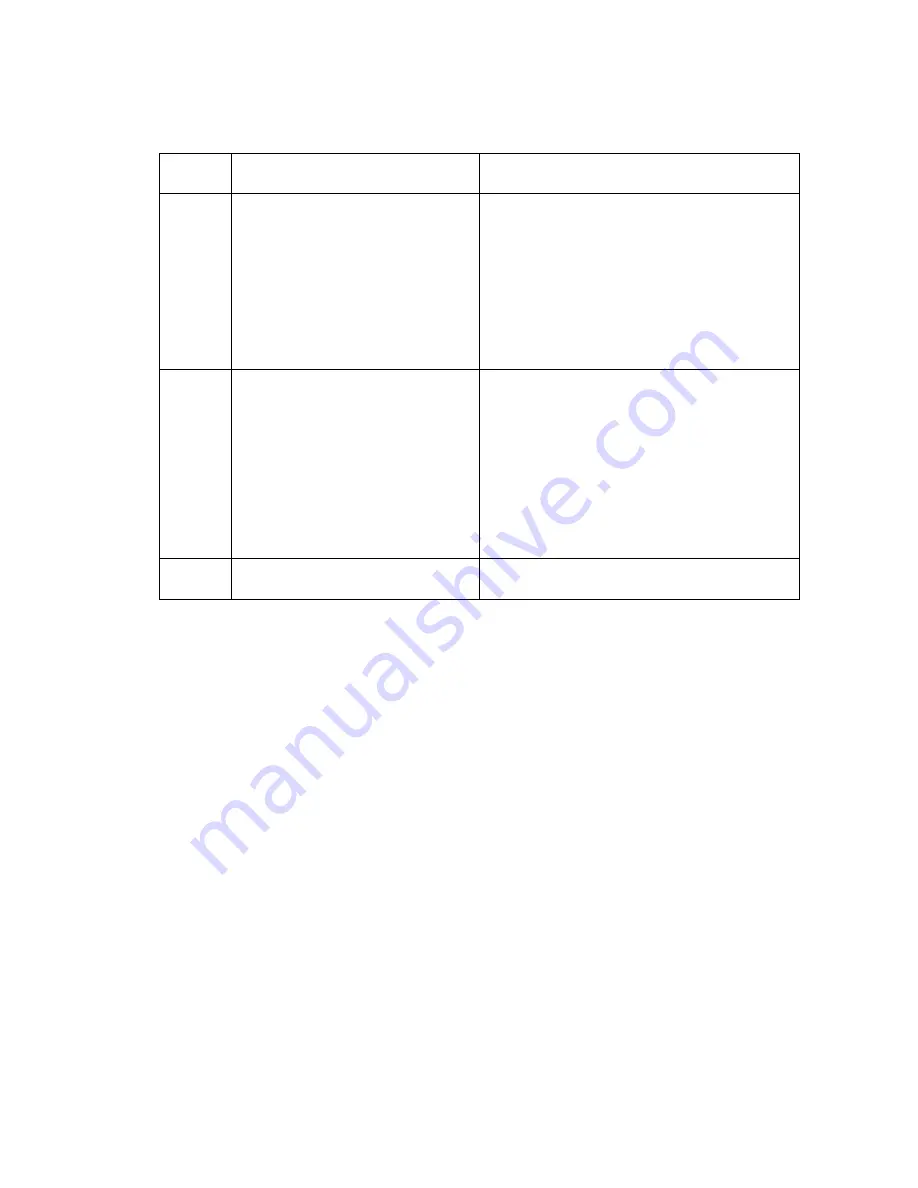

Selector

No.

Function

Setting and Specifications

1

|

3

Delay time from when documents

are set until the ADF starts drawing

them in

No. 1 2 3

0 0 0 : No automatic drawing-in

0 0 1 :

1 sec.

0 1 0 :

2 sec.

0 1 1 :

3 sec.

1 0 0 :

4 sec.

1 0 1 :

5 sec.

1 1 0 :

6 sec.

1 1 1 :

7 sec.

4

|

6

Periodical correction intervals of

the reference voltage to be applied

to white level compensation for

document scanning, during standby

No. 4 5 6

0 0 0 : No correction of reference

voltage during standby

0 0 1 :

10 sec.

0 1 0 :

30 sec.

0 1 1 :

1 min.

1 0 0 :

3 min.

1 0 1 :

5 min.

1 1 0 :

10 min.

1 1 1 :

30 min.

7

8

Not used.

NOTE:

WSW45 is applicable only to models equipped with a flat-bed scanner.

Selectors 1 through 3: Delay time from when documents are set until the ADF starts drawing them in

These selectors determine how long the ADF will delay automatic drawing-in of documents (to the

scanning standby position) after you set them in the ADF, as well as determining whether or not

the ADF automatically draws in documents.

Selectors 4 through 6: Periodical correction intervals of the reference voltage applied to white level

compensation for document scanning, during standby

These selectors set the correction intervals (in seconds) of the reference voltage to be applied to

white level compensation for document scanning during standby, as well as determining whether

or not the controller makes the reference voltage correction during standby. (Conventionally, the

correction has been made immediately before the start of actual scanning)

This function takes effect in copying. Making the correction during standby may shorten the

preparation time for copying.

NOTE:

Do not access these selectors.

Содержание Laser MFC-4800

Страница 1: ...FACSIMILE EQUIPMENT SERVICE MANUAL MODEL FAX2800 FAX2900 FAX3800 MFC4800 FAX8070P MFC9030 MFC9070 ...

Страница 5: ...CHAPTER 1 GENERAL DESCRIPTION ...

Страница 16: ...CHAPTER 2 INSTALLATION ...

Страница 21: ...CHAPTER 3 THEORY OF OPERATION ...

Страница 23: ...3 1 3 1 OVERVIEW ...

Страница 26: ...3 4 3 2 2 Laser Printing Mechanism 3 2 2 1 Paper pulling in registration feeding and ejecting mechanism ...

Страница 31: ...3 9 Location of Sensors and Actuators ...

Страница 33: ...CHAPTER 4 DISASSEMBLY REASSEMBLY AND LUBRICATION ...

Страница 39: ...4 4 Disassembly Order Flow ...

Страница 44: ...4 9 6 Turn the ASF upside down then remove the registration sensor actuator ...

Страница 82: ...4 45 Harness routing G Laser diode harness polygon motor flat cable and toner sensor harness on the laser unit ...

Страница 86: ...4 48 2 Scanner drive unit 3 Separation roller ...

Страница 87: ...4 49 4 Document feed roller ...

Страница 88: ...CHAPTER 5 MAINTENANCE MODE ...

Страница 95: ...5 6 Scanning Compensation Data List a b c d e ...

Страница 102: ...5 13 Key Button Entry Order ...

Страница 110: ...CHAPTER 6 ERROR INDICATION AND TROUBLESHOOTING ...

Страница 140: ...FAX2800 FAX2900 FAX3800 MFC4800 FAX8070P MFC9030 MFC9070 Appendix 1 EEPROM Customizing Codes ...

Страница 143: ...FAX2800 FAX2900 FAX3800 MFC4800 FAX8070P MFC9030 MFC9070 Appendix 2 Firmware Switches WSW ...

Страница 190: ...A Main PCB 1 5 ...

Страница 191: ...A Main PCB 2 5 ...

Страница 192: ...A Main PCB 3 5 ...

Страница 193: ...A Main PCB 4 5 ...

Страница 194: ...A Main PCB 5 5 ...

Страница 195: ...B NCU PCB U S A Canada ...

Страница 196: ...B NCU PCB U K Norway Netherlands Finland Denmark Sweden ...

Страница 197: ...B NCU PCB Germany France Belgium Switzerland Ireland Austria Spain Italy South Africa ...

Страница 198: ...B NCU PCB Asia Oceania 1 2 ...

Страница 200: ...C Control Panel PCB ...

Страница 201: ...D Power Supply PCB 100 120V Low voltage power supply ...

Страница 202: ...D Power Supply PCB 200 240V Low voltage power supply Europe ...

Страница 203: ...D Power Supply PCB 200 240V Low voltage power supply Asia Oceania ...

Страница 204: ...D Power Supply PCB High voltage power supply ...

Страница 205: ...April 02 SM FAX002 8X5601 Printed in Japan ...