9. STANDARD ADJUSTMENTS

DA-927A, DA-928A

23

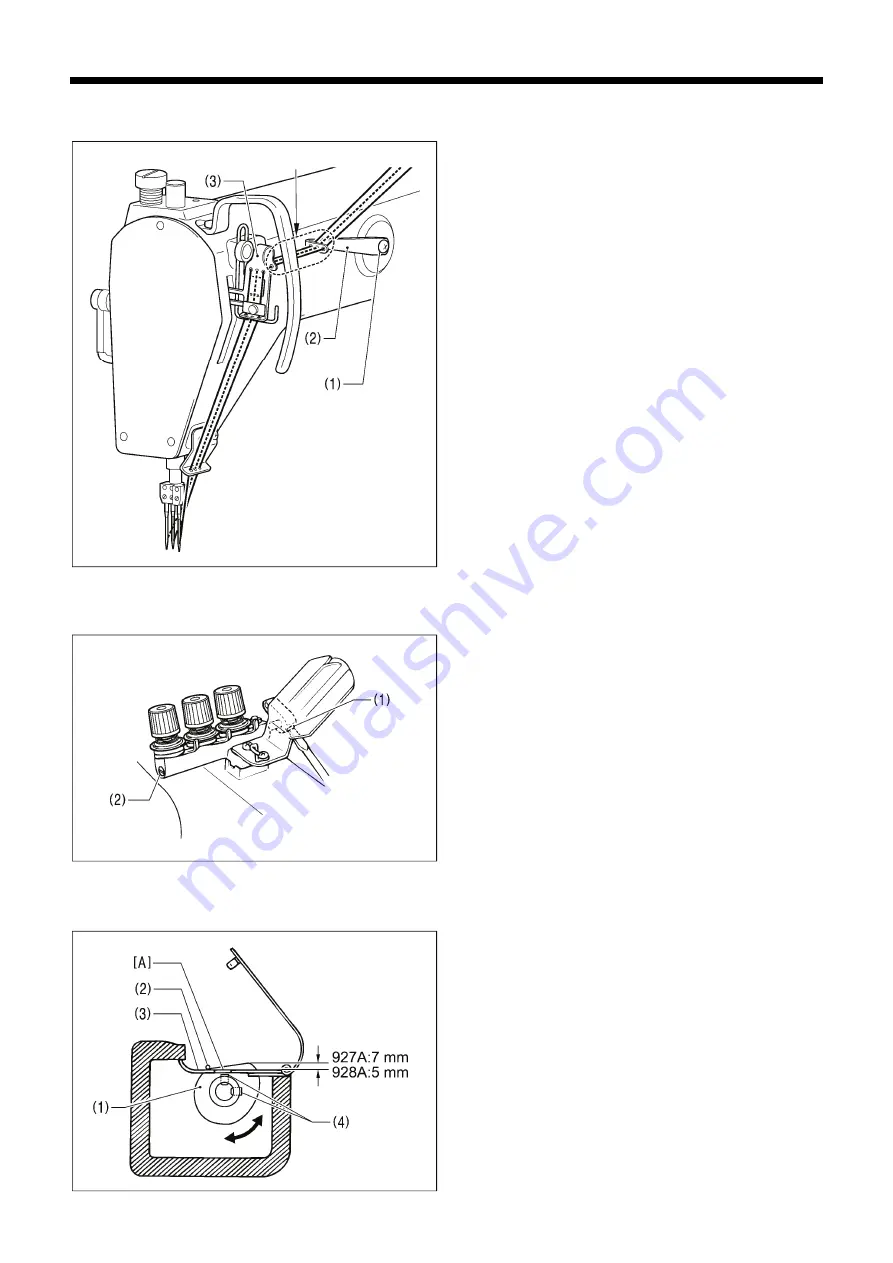

9-8. Adjusting the upper thread guide

1. Turn the machine pulley toward you to move the needle to

its highest position.

2. Loosen the screw (1), and then adjust the upper thread guide

(2) so that the upper thread is almost horizontal from the

upper thread guide (2) to the upper thread take-up (3).

3. After adjusting, tighten the screw (1).

* When the upper thread guide (2) is move up, the thread

tightening improves.

9-9. Tension release shaft adjustment

Adjust the tension release shaft so that the tension discs loosen

when the presser foot is raised and tighten when the presser

foot is lowered.

1. Loosen set screw (1).

2. Make an adjustment by turning the tension release shaft (2)

so that the tension discs begin to loosen when the presser

foot rises 1 - 3 mm above the top of the needle plate.

3. After the adjustment, retighten the set screw (1) securely.

9-10. Lower thread take-up timing adjustment

Adjust so that the lower thread take-up (1) touches the thread (2)

when the looper starts its backward travel.

1. Insert the screwdriver through the adjusting hole [A] in the

lower thread take-up base (3), and loosen the two set screws

(4).

2. Turn the machine pulley to raise the needle bar to its highest

position.

3. Raise the lower thread take-up (1) 7 mm [for the 927A] or 5

mm [for the 928A] above the lower thread take-up base (3).

In addition, adjust so that the clearances at left and right are

approximately equal.

4. After the adjustment, retighten the two set screws (4)

securely.

4334B

Thread should be horizontal

4333B

4281B

Содержание DA-927A

Страница 6: ...DA 927A DA 928A v 4284B Oil tank ...