9. STANDARD ADJUSTMENTS

DA-927A, DA-928A

21

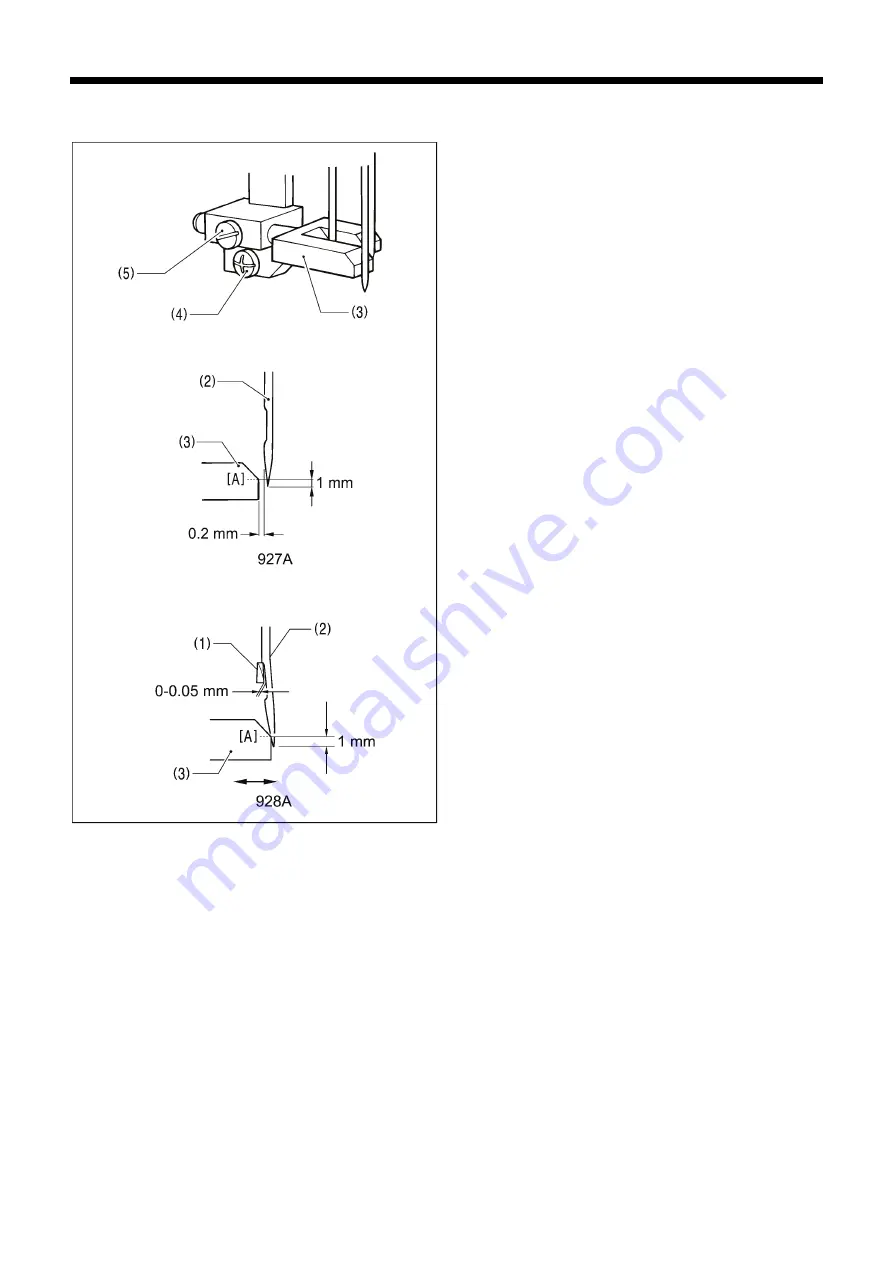

9-5. Needle guard adjustment

1. Set the actual stitch length. (Refer to “7-3. Adjusting the stitch

length”.)

2. Turn the machine pulley toward you by hand until the looper

(1) tip is aligned with the needle (2) center while the looper is

moving forward.

3. Loosen the set screw (4), and then move the needle guard

(3) up or down to adjust so that the distance between the

ridge line [A] of the needle guard (3) tip and the needle (2) tip

is 1 mm.

4. Tighten the set screw (4).

5. Loosen the set screw (5), and then move the needle guard

(3) to the left or right to adjust so that the clearance between

the needle (2) and the needle guard (3) is 0.2 mm (for the

927A) or so that the clearance between the needle (2) and

the tip of the looper (1) is 0 to 0.05 mm when the needle

guard (3) is pushing the needle (2) (for the 928A).

6. Tighten the set screw (5).

NOTE:

Be sure to adjust the needle guard (3) after changing the

stitch length. If you use the sewing machine without

adjusting the needle guard (3), skipped stitches may occur

or the looper tip may become broken.

4332B

1524B

4331B

Содержание DA-927A

Страница 6: ...DA 927A DA 928A v 4284B Oil tank ...