Not for

Reproduction

14

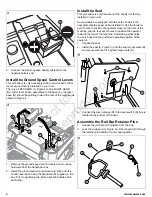

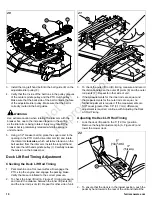

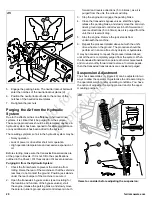

7. Set the mower deck to the 3-1/2” (8,9 cm) cutting

position.

8. Measure the coil-to-coil length (J) of the idler arm spring

(K). The measurement should equal 6-1/8" (15,6 cm) ±

1/8 (0,32 cm). If not, turn the adjustment nut (L) until the

measurement is achieved.

9. Tighten the jam nut and the 3/8" nut that secures the rear

back side idler pulley to the deck.

Check the Long Left Hand Deck Belt

NOTICE

To avoid damaging belt,

do not pry over

pulleys.

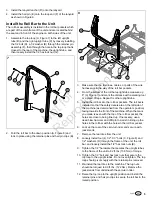

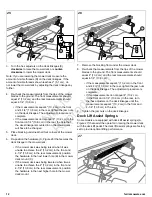

1. Check the routing of the long left hand belt (A, Figure

30). Make sure that the V-side of the belt is in the pulley

grooves of the left hand spindle pulley (B), center spindle

pulley (C), and the PTO clutch pulley (D). Make sure

that the back side of the belt contacts the fact of the

adjustable idler pulley (E). Make sure that the belt is

correctly routed in the belt guides (F & G).

30

WARNING

Use extreme caution when rotating the idler arm with the

breaker bar, due to the increased tension in the spring

as the idler arm as being rotated. Injury may result if the

breaker bar is prematurely released while the spring is

under tension.

2. If the long left hand belt is not properly seated, use a 1/2”

breaker bar (H) and place the square end in the opening

in the spindle drive idler arm (I) and rotate the idler arm

clockwise

, which will relieve the tension on the belt

exerted from the idler arm.

3. Re-seat the long left hand belt and carefully release the

tension on the idler arm.

4. Set the mower deck to the 3-1/2” (8,9 cm) cutting

position.

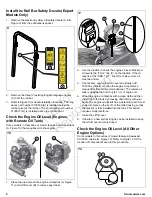

5. Measure the coil-to-coil length (A, Figure 31) of the long

left hand belt tensioning spring (B). The measurement

should equal 10-1/4" (26 cm) ± 1/8 (0,32 cm). If not,

loosen the jam nut (C) on the eye bolt (D) and then turn

the adjustment nut (E) until the measurement is achieved.

Tighten the jam nut.

31

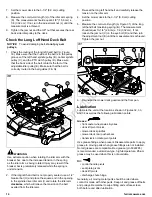

6. Re-install the mower deck guards and the floor pan.

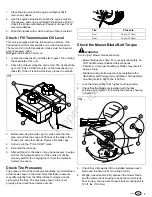

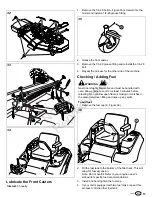

Lubrication

Lubricate the unit at the locations shown in Figures 32, 33,

and 34 as well as the following lubrication points:

Grease:

• front caster wheel axles & yokes

• deck lift pivot blocks

• mower deck spindles

• mower deck rear pusher bars

• transmission cradle pivot points

Use grease fittings when present. Disassemble parts to apply

grease to moving parts when grease fittings are not installed.

Not all greases are compatible. Red grease (p/n 5022285)

is recommended, automotive-type, high-temperature, lithium

grease may be used when this is not available.

Oil:

• control handle pivots

• seat plate pivots

• deck lift pivots

• discharge chute hinge

Generally, all moving metal parts should be oiled where

contact is made with other parts. Keep oil and grease off belts

and pulleys. Remember to wipe fitting and surfaces clean

both before and after lubrication.

Содержание IS3200Z Series

Страница 1: ...N o t f o r R e p r o d u c t i o n ...

Страница 23: ...N o t f o r R e p r o d u c t i o n Notes ...

Страница 24: ...N o t f o r R e p r o d u c t i o n ...