Installation

Supplies Required:

• (3) 3/8" bolts and wall anchors for mounting

wall bracket

• Pipe sealant

• Piping to 1/2" IPS water supply inlet on unit

• Piping to 1-1/4" IPS drain outlet

• Sign-mounting hardware

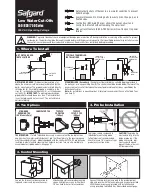

Step 1: Install inlet drain fittings

NOTE: The top of the eyewash heads should

be 33"–45" (838mm–1143mm) from the floor.

1. Position the inlet drain fitting over the 1-

1/4" drain outlet pipe from wall.

2. Using the inlet drain fitting as a template,

mark the bolt hole locations on the wall

OR install three suitable fasteners

(supplied by installer) for 3/8" bolts in the

wall at the marked hole locations (see

Figure 1).

3. Bolt the inlet drain fitting to the wall or

wall fasteners using 3/8" bolts (supplied

by installer).

Step 2: Assemble eyewash

components

1. Assemble eyewash components as shown

in Figure 2a on page 4 or Figure 2b on

page 5.

• Apply pipe sealant (supplied by

installer) to all male-threaded pipe

joints.

• Use a strap wrench around pipes when

tightening to prevent marring.

Step 3: Connect water supply

1. Connect the water supply piping (supplied

by installer) to the 1/2" IPS inlet on the

eyewash.

2. Connect the tailpiece to the 1-1/4" IPS

drain outlet on the eyewash.

3. Mount the safety sign to the wall using

sign-mounting hardware (supplied by

installer).

4. Open the water supply lines. Test for leaks

and adequate water flow.

29-1/2"

(749mm)

S

u

gg

e

s

ted

Hei

g

ht

To Floor

15-1/2" (

3

94mm)

8

-1/

8

"

(206mm)

2-1/4"

(57mm)

5-1/4"

(1

33

mm)

7-1/2"

(191mm)

4"

(102mm)

Ø

3

/

8

"

(9mm)

8

-1/4"

(210mm)

4-1/2"

(114mm)

Ø 10" (254mm)

1

3

-1/4"

(

33

7mm)

3

6" (914mm)

S

u

gg

e

s

ted

Hei

g

ht

To Floor

Wall

29-1/2"

(749mm)

S

u

gg

e

s

ted

Hei

g

ht

To Floor

8

-1/

8

"

(206mm)

2-1/4"

(57mm)

5-1/4"

(1

33

mm)

7-1/2"

(191mm)

4"

(102mm)

Ø

3

/

8

"

(9mm)

8

-1/4"

(210mm)

4-1/2"

(114mm)

3

6" (914mm)

S

u

gg

e

s

ted

Hei

g

ht

To Floor

Ø 10-

3

/4" (27

3

mm)

(1

3

-5/

8

")

3

46mm

15-7/

8

" (40

3

mm)

Wall

3

Installation

S19-220FW, S19-220T

Bradley Corporation • 215-158FW Rev. J; EN 06-532E

4/20/07

Figure 1

S19-220T

S19-220FW