6 720 608 032

10

Installation instructions

Masonry chimney

Masonry chimneys shall be built and installed in

accordance with NFPS 211 or local codes. A minimum

5" diameter gas vent pipe (metal double wall Type B),

or an approved clay flue liner or a listed chimney lining

system must be used when venting into a naturally

drafting, internal masonry chimney. 6 inch is required in

elevations greater than 2000 feet, see Fig. 10. Local

codes may require the use of both gas vent and an

approved lining system when venting into a masonry

chimney. The Commonwealth of Massachusetts

requires the use of a listed liner. Lining systems include

approved clay flue lining, a listed chimney lining system

or other approved material that will resist corrosion,

erosion, softening, or cracking from exhaust flue gases

at temperatures up to 1800 degrees F. The lining

system must be listed for use with naturally drafting,

draft hood equipped gas appliances. Follow local

codes and refer to NFGC 54 and NFPA 58.

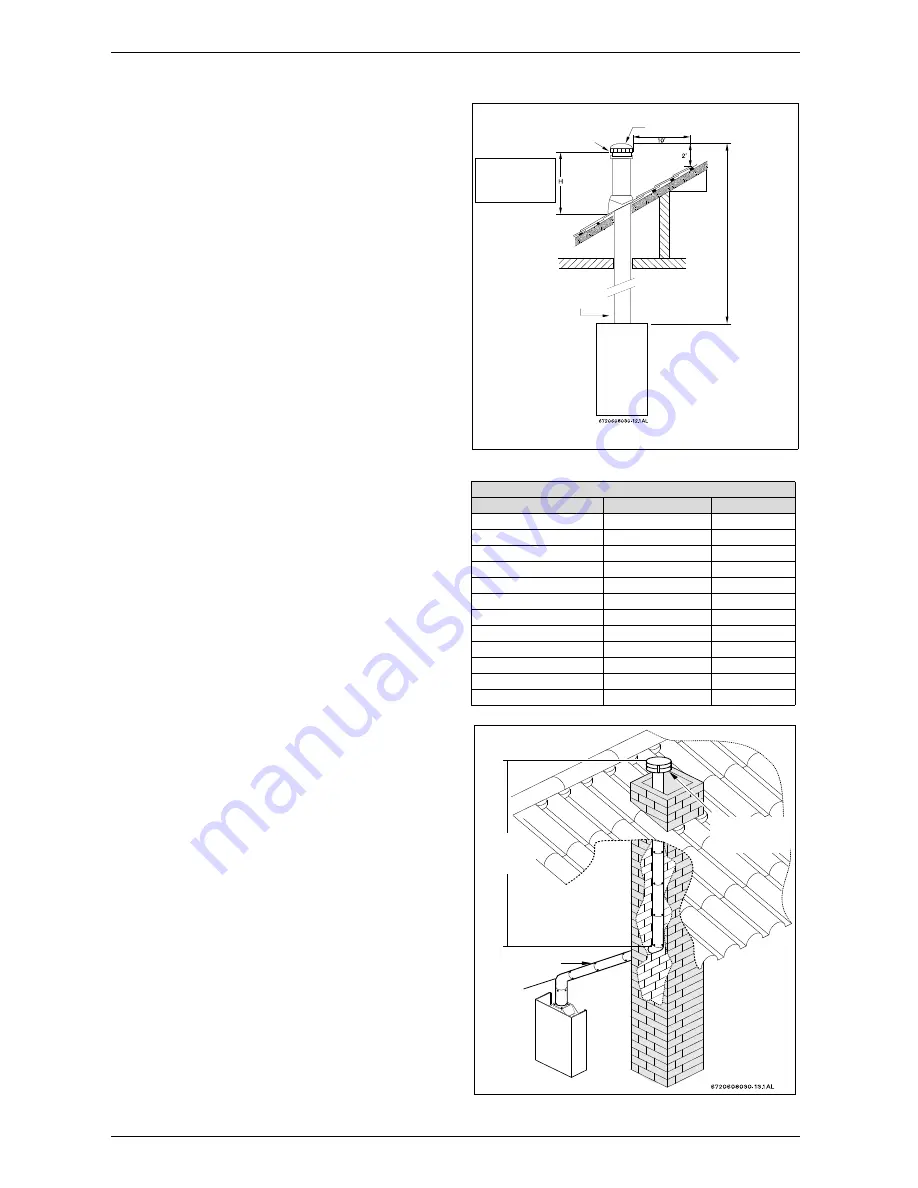

Existing interior masonry chimney

The metal gas vent pipe should be permanently

mounted inside the masonry chimney. Double wall Type

B gas vent is recommended. The masonry chimney may

have to be tile or metal lined before the insertion of the

gas vent pipe; check local codes for clarification. The

lining material must be listed for use only with naturally

drafting, draft hood equipped gas appliances. Follow

manufactures instructions for installation of listed lining

material. You may not vent any other fuel burning

appliances into any free space remaining in the

chimney. The minimum vertical gas vent length within

the masonry chimney should be no less than 5 ft (1.5

m); the vent terminator should extend at least 3 feet (0.9

m) above where the chimney meets the roofline and at

least 2 feet (0.6 m) higher than any vertical wall or

similar obstruction within 10 feet (3.1 m). The top of the

gas vent should have an approved vent terminator. See

Fig. 12.

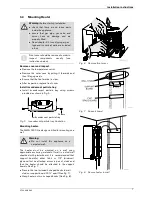

Fig. 11 Pitch roof

Fig. 12 Masonry chimney

GAS VENT TERMINATIONS FOR LISTED VENT CAPS

Roof pitch

H (minimum) feet

meters

Flat to 6/12

1.0

0.30

6/12 to 7/12

1.25

0.38

Over 7/12 to 8/12

1.5

0.46

Over 8/12 to 9/12

2.0

0.61

Over 9/12 to 10/12

2.5

0.76

Over 10/12 to 11/12

3.25

0.99

Over 11/12 to 12/12

4.0

1.22

Over 12/12 to 14/12

5.0

1.52

Over 14/12 to 16/12

6.0

1.83

Over 16/12 to 18/12

7.0

2.13

Over 18/12 to 20/12

7.5

2.27

Over 20/12 to 21/12

8.0

2.44

Table 2

LISTED VENT CAP

LOWEST DISCHARGE

OPENING

MINIMUM 6

FEET (1.8M)

X

12

ROOF

PITCH IS

X/12

LISTED GAS VENT

H (minimum) height

from roof to lowest

discharge opening

ESTABLISH A ONE

FOOT RISE BEFORE

ANY ELBOWS

GAS

VENT

LISTED

VENT CAP

VENT

CONNECTOR

Establish a

one foot

rise before

any elbows