8

• Use personal protective equipment . Always wear eye

protection . Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries .

• Prevent unintentional starting . Ensure the switch is in

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool .

Carrying power tools with your finger on the switch or

energising power tools that have the switch on invites

accidents .

• Remove any adjusting key or wrench before turning the

power tool on . A wrench or a key left attached to a rotat-

ing part of the power tool may result in personal injury .

• Do not overreach . Keep proper footing and balance at

all times . This enables better control of the power tool in

unexpected situations .

• Dress properly . Do not wear loose clothing or jewellery .

Keep your hair, clothing and gloves away from moving

parts . Loose clothes, jewellery or long hair can be caught

in moving parts .

• If devices are provided for the connection of dust extrac-

tion and collection facilities, ensure these are connected

and properly used . Use of dust collection can reduce

dust-related hazards .

Power tool use and care

• Do not force the power tool . Use the correct power tool

for your application . The correct power tool will do the

job better and safer at the rate for which it was designed .

• Do not use the power tool if the switch does not turn

it on and off . Any power tool that cannot be controlled

with the switch is dangerous and must be repaired .

• Disconnect the plug from the power source and/or the

battery pack from the power tool before making any ad-

justments, changing accessories, or storing power tools .

Such preventive safety measures reduce the risk of start-

ing the power tool accidentally .

• Store idle power tools out of the reach of children and do

not allow persons unfamiliar with the power tool or these

instructions to operate the power tool . Power tools are

dangerous in the hands of untrained users .

• Maintain power tools . Check for misalignment or binding

of moving parts, breakage of parts and any other condi-

tion that may affect the power tool’s operation . If dam-

aged, have the power tool repaired before use . Many

accidents are caused by poorly maintained power tools .

• Keep cutting tools sharp and clean . Properly maintained

cutting tools with sharp cutting edges are less likely to

bind and are easier to control .

• Use the power tool, accessories and tool bits etc . in ac-

cordance with these instructions, taking into account the

working conditions and the work to be performed . Use

of the power tool for operations different from those in-

tended could result in a hazardous situation .

Service

Have your power tool serviced by a qualified repair person

using only identical replacement parts . This will ensure

that the safety of the power tool is maintained .

HAMMER SAFETY WARNINGS

• Observe the mains voltage! The voltage of the power

source must correspond with the data on the type plate

of the machine . Power tools marked with 230/240 V can

also be operated with 220 V .

• Use appropriate detectors to determine if utility lines are

hidden in the work area or call the local utility company

for assistance . Contact with electric lines can lead to fire

and electric shock . Damaging a gas line can lead to explo-

sion . Penetrating a water line causes property damage .

• Firmly tighten the auxiliary handle, hold the machine

firmly with both hands while working and keep proper

footing and balance at all times . The machine is securely

guided with both hands .

• Secure the workpiece . A workpiece clamped with clamp-

ing devices or in a vice is held more secure than by hand .

• For drilling without impact in wood, metal, ceramic and

plastic as well as for screwdriving, tools without SDS-

plus are used (e .g ., drill bits with cylindrical shank) . For

these tools, a keyless chuck or a key type drill chuck are

required .

• The quick change chuck is automatically locked . Check

the locking effect by pulling the quick change chuck .

• Inserting SDS-plus Drilling Tools: Check the latching by

pulling the tool .

• Replace a damaged dust protection cap immediately .

The dust protection cap largely prevents the penetra-

tion of drilling dust into the tool holder during operation .

When inserting the tool, pay attention that the dust pro-

tection cap is not damaged .

• To save energy, only switch the power tool on when us-

ing it .

• Dusts from materials such as lead-containing coatings,

some wood types, minerals and metal can be harmful

to one’s health and cause allergic reactions, lead to res-

piratory infections and/or cancer . Materials containing

asbestos may only be worked by specialists .

• As far as possible, use a dust extraction system suitable

for the material .

• Provide for good ventilation of the working place .

• It is recommended to wear a P2 filter-class respirator .

• Observe the relevant regulations in your country for the

materials to be worked .

• Prevent dust accumulation at the workplace . Dusts can

easily ignite .

• If the application tool should become blocked, switch

the machine off . Loosen the application tool .

• Before switching on the power tool, make sure that the

application tool moves freely . When switching on with

a blocked drilling tool, high torque reaction can occur .

• Always wait until the machine has come to a complete

stop before placing it down . The tool insert can jam and

lead to loss of control over the power tool .

MAINTENANCE AND CLEANING

Make sure that the machine is not live when carrying

out maintenance work on the motor .

• Regularly clean the machine housing with a soft cloth,

preferably after each use . Keep the ventilation slots free

from dust and dirt .If the dirt does not come off use a soft

cloth moistened with soapy water . Never use solvents

such as petrol, alcohol, ammonia water, etc . These sol-

vents may damage the plastic parts .

• Every six months it is recommended to take your ma-

chine to Service Center to change the grease .

Содержание 93410716

Страница 1: ...BHD 800x2 93410716 RU FR DE GB Bohrhammer 5 Rotary hammer 7 Marteau perforateur 9 12...

Страница 2: ...2 2 3 4 H H 800 W 220 V 50 Hz 5 400 min 1 3 5 J 30 mm 26 mm 13 mm 3 2 kg 0 1420 0 2980 min 1...

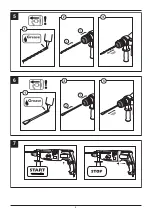

Страница 3: ...3 5 2 1 2 1 6 7...

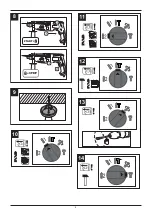

Страница 4: ...4 8 9 10 4 2...

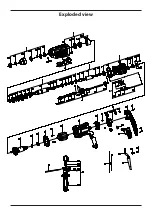

Страница 16: ...Exploded view...

Страница 18: ...18 RU FR DE GB Garantiebedingungen Warranty terms Conditions de garantie...

Страница 24: ...24 BORT GLOBAL LIMITED BORT GLOBAL LIMITED 2 Defort 5 SDS BORT GLOBAL LIMITED GmbH 21 10719...

Страница 25: ......

Страница 28: ......

Страница 29: ...29 bort global com...

Страница 30: ...30...

Страница 31: ...31...