4

4

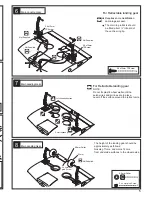

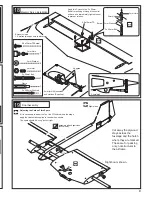

To Make the Pushrods to the length required;-

(1)

Make a 90 degree bend in the wire at the length required

to meet the output hole in the servo arm with the servo

centred.

(2) Now make a second bend off at 90 degrees to the first one,

left or right, in the wire at approx. 3mm away from the first

bend.

(3) Straighten the wire by gripping each side of the “Z” bend

with pliers and slowly turning until the ends are in line. Now

cut off the excess wire. The output hole in the servo arm

may have to be drilled out to accommodate the “Z” bend

wire passing through it. Adjustment of the pushrod length

is carried out by adjusting the clevis along the threaded

part of the pushrod.

An extra pushrod is supplied to allow for possible error.

13

28

27

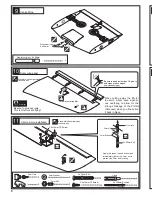

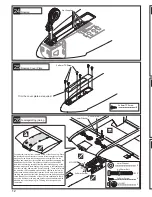

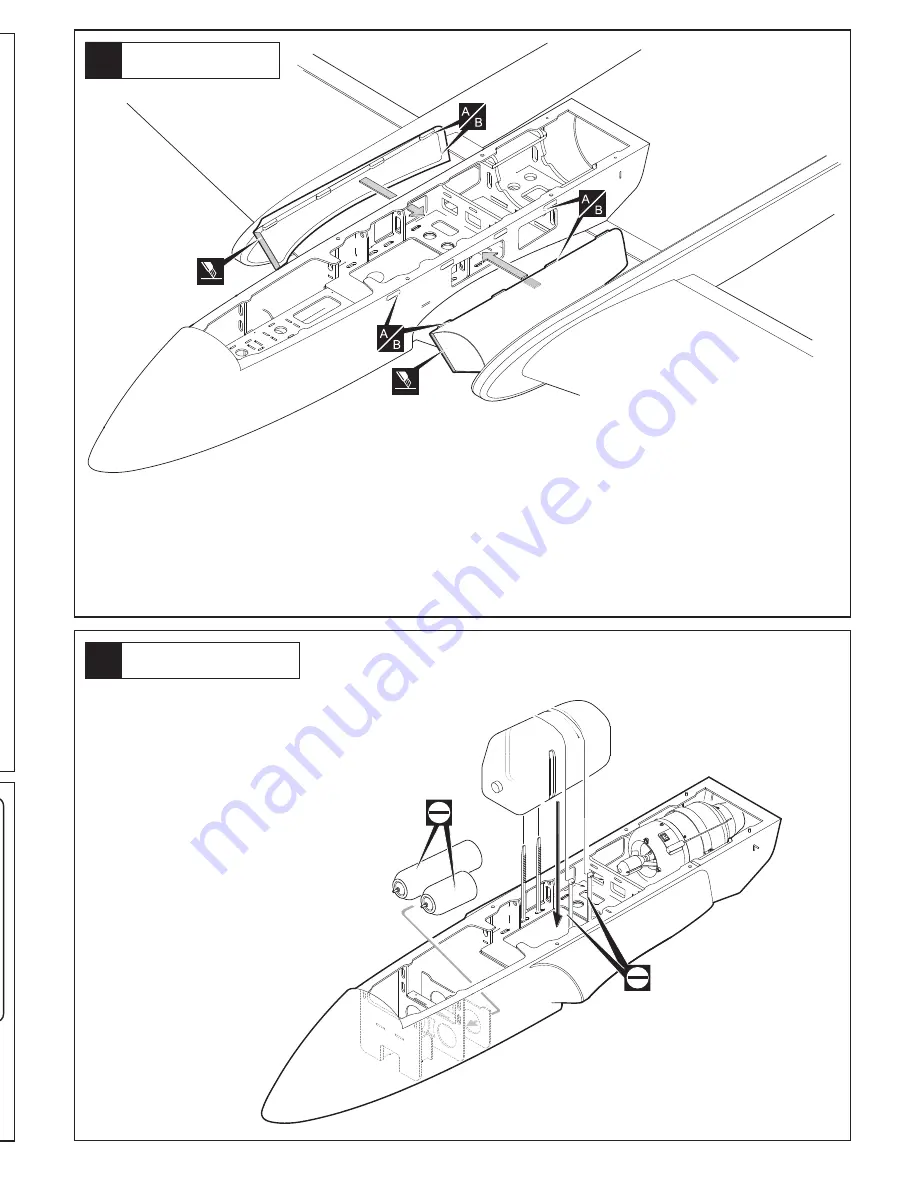

Fuel Tank etc

Pushrods

Cut

90

90

90

5

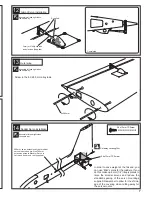

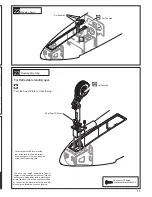

Flap control

Note hinge position and the control horn

Rearward to allow maximum 90 degree

downward movement for the flap.

Assemble left and right sides

the same way.

2mm.pushrods and clevises (Supplied)

Supplied

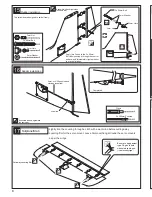

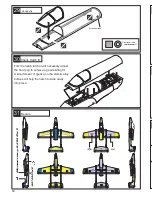

Air Intakes

Cut away covering film.

Cut away covering film.

A custom Sullivan 3.7 litre fuel tank made for this kit

is available from your Boomerang Jets dealer.

Otherwise it is possible to fit any container from 2

litres up by modifying the fuselage formers as

required. Ensure that the tank is well secured by

using long cable tie wraps through the formers. Do

not simply depend on the tank bay floor for this. A

full tank of fuel weighs anything up to 8 Lbs (4 Kilos)

and in a negative G manoeuvre can exert consider-

able upward pull.

Clean up the front opening of the air intakes as necessary. After carefully

stripping away covering film from the small cutouts in the supper fuselage use the

air intakes as a guide to how much covering to remove from each side of the

fuselage, opening up the airflow openings each side and leaving a bare wood

gluing surface just a few mm. smaller than the intakes all around ready to fix the

intakes using think CA glue. The air intake is glued to the fuselage only, not to the

wing.