22

The following is a brief overview of some representative Menu options:

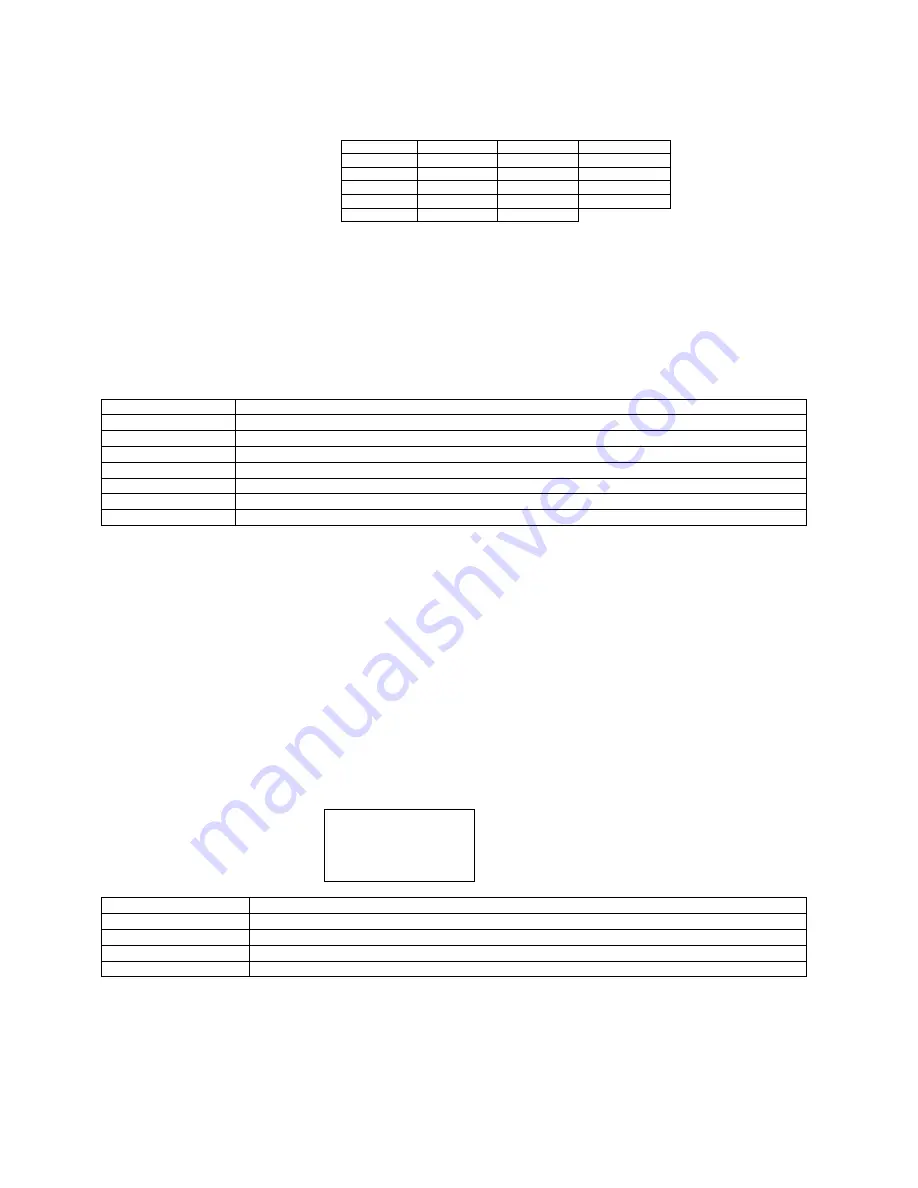

BAUD RATE? Controls the serial interface baud rate, parity bit, data bits and stop bits.

Here are the following choices:

MINI/MICRO? Defines the type of printer.

MINI

Is for a printer with a Silent Cutter Assembly (SC2) (Mini, Mini Plus, Mini MB, Dual Mini)

MICRO Is for a printer without a SC2 (Micro, Micro Plus, Micro MB, Dual Micro)

PRINT SPEED? Controls the speed the ticket travels at. Also effects the print quality.

The numbers range from 0 - FASTEST to 7 - SLOWEST. 3 is factory default.

DIAGNOSTIC MODE

????

Your choices are YES or NO. NO is factory default. (Please consult your Programming Guide)

TICKET TYPE? Factory setting. Do not modify.

STATUS ENABLED? Sets status response protocols.

NONE

Disables the XON/XOFF and status response protocols

SERIAL

Enables the XON/XOFF and status response protocol for the serial port.

PARALLEL

Enables bi-directional parallel status responses if printer is configured as bi-directional.

SER/PAR

Enables both bi-directional parallel and serial status responses.

USB

Enables USB status responses

USB/SER

Enables USB and serial status responses

USB/PAR

Enables USB and bi-directional parallel

USB/SER/PAR

Enables USB, bi-directional parallel and serial status responses

TRANSPARENT MODE? YES (Enabled) or NO (Disabled). (Please consult your Programming Guide)

PAPER MODE? Is generally used only for test purposes. It may also be used on roll stock with no black marks on the ticket. Your

choices are YES (Enabled) or NO (Disabled). NO is factory default.

INC CUT1/2 COUNT? moves the cut/tear position to the left (towards the ticket entrance area). Cut counts are increments of .003” for

300dpi and .005” for 200dpi. Depressing CHOICES changes the count value. 16 is factory default. (1 is for path one; 2 is for path 2

[dual only])

DEC CUT1/2 COUNT? moves the cut/tear position to the right (towards the ticket exit area). Cut counts are decrements of .003” for

300dpi and .005” for 200dpi. Depressing CHOICES changes the count value. 16 is factory default.

PRINT MODE? Defines the automatic ticket length calculation feature.

THERMAL The printer will feed out and then retract a ticket during this measurement.

RIBBON The printer will feed out one blank ticket. This mode is used for label stock to prevent peeling.

PRINT INTENSITY? Controls the darkness of ticket print out.

Here are the following choices:

TEST TICKET?

Defines they type of self-test ticket printed.

STANDARD

Normal self test ticket pattern (factory default)

CONFIGURATION 1

To print configuration settings if printing on a 1” wide ticket

CONFIGURATION 2

To print configuration settings if printing on a 2” wide ticket

CONFIGURATION 3

To print configuration settings if printing on a 3” wide ticket

CONFIGURATION 4

To print configuration settings if printing on a 4” wide ticket

EXIT AND SAVE ! Will save any changes made to the above menu options.

If you wish to save the new value then press TEST, if not press MENU.

JUST EXIT? Will exit the menu options without saving any changes.

If you with to exit without saving the new value then press TEST, if not press MENU.

1200,N,8,1

4800,N,8,1

19200,N,8,1

38400,E,7,1

1200,E,7,1

4800,E,7,1

19200,E,7,1

57600,N,8,1

1200,O,7,1

4800,O,7,1

19200,0,7,1

57600,E,7,1

2400,N,8,1

9600,N,8,1

28800,N,8,1

115200,N,8,1

2400,E,7,1

9600,E,7,1

28800,E,7,1

115200,E,7,1

2400,O,7,1

9600,0,7,1

38400,N,8,1

LIGHT

MED LIGHT

NORMAL

(factory default)

MED DARK

SHORT HEAD LIFE