NOTE: Use of partially used

load strips.

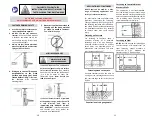

If you want to use a partially fired load

strip, the end of the strip containing

the live loads should be placed into

the bottom of the tool handle. Count

the number of unfired loads in the

strip before inserting it and keep a

count as the fastenings are being

made, you can easily determine when

all the loads have been used.

13

6.

Check the tool frequently to ensure

that the muzzle bushing and loads

strip track are clear, if you are

working at a site with dirt and

debris.

CHECK THE NOSEPIECE BUSHING

AND LOAD STRIP TRACK FOR

DEBRIS

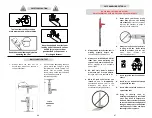

IF YOU DECIDE NOT TO MAKE A

FASTENING AFTER THE TOOL HAS

BEEN LOADED, ALWAYS REMOVE

THE POWDER LOADS FIRST, THEN

THE FASTENER. THIS WILL PREVENT

ACCIDENTAL DISCHARGING OF THE

FASTENER OR PISTON INTO THE

OPERATION HAND.

Please watch the videos on our website:

http://bpfasteners.com/licensing/video

5.

After all 10 shots are fired, pull the

load strip from the

TOP

of the tool.

NEVER

PULL

IT

FROM

THE

BOTTOM.

4.

After one shot is fired, point it in a

safe direction and insert the next

fastener into the Nosepiece, and

then press the Advance Lever

Assembly

of

the

housing

to

advance the next load, and repeat

the firing operation.

BP-27C OPERATING INSTRUCTIONS

12

BP-27C IS NOT A STAND-ALONE TOOL.

IT MUST ALWAYS BE USED MOUNTED ON A BLUE POINT POLE.

DO NOT USE EXCESSIVE

FORCE WHILE INSERTING A

FASTENER

3.

Raise the tool upwards carefully

without bumping any other object

and gently place it on the ceiling

where you want to fasten. Hold it

perpendicular to the work surface

and push upwards to compress the

firing pin spring and release the

sear to fire the tool.

If the tool

does not fire, hold the tool for 30

seconds and then follow the

misfire procedure described on

page 10.

2.

With the tool pointing in a safe

direction and your fingers off the

Advance Lever, insert the strip load

through the bottom of the handle

and push through until your fingers

touch the handle recess.

Never try

to insert a load strip into the tool

from the top of the receiver.

1.

After checking to make sure that the

tool is not loaded, point it in a safe

direction and insert a fastener into

the

Nosepiece of the tool until it is

fully seated. If a clip assembly is

being used, be sure it is positioned in

the cutout section of the Spall Guard.

Содержание BP-27C

Страница 12: ...23 NOTES 22 NOTES ...