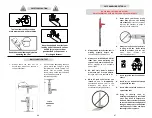

Suitable Base Materials:

Only the following materials are suitable

for Powder-actuated fastening:

•

Structural Steel

•

Masonry Joints

•

Poured Concrete

DO NOT try to fasten into any other

type of materials.

It can cause serious

injury or blindness.

Unsuitable Base materials that should

not be fastened to:

Never try to fasten into very hard or

brittle materials such as tile, glass, cast

iron or rocks of any kind.

These

materials can break, or shatter causing

splinters to fly and may cause serious

injury to the tool operator and the

bystanders.

PREPARATION

BP-27C is a semi-automatic feeding low velocity powder-actuated fastening

tool. Continuous feeding of powder loads for a wide range of applications,

make the BP-27C tool a versatile, portable, safe and reliable tool.

INTRODUCTION

Never attach directly to a base

where it can easily penetrate like

wood or gypsum board.

These

types of materials may cause the

fasteners to penetrate through to the

other side making it dangerous for

other people in the work area.

Never fasten into a base material

that fails the center punch test.

Failure to check the suitability of the

base material can cause serious

injury to the eyes or other body parts.

Never try to fasten into very hard

or brittle materials.

Never attach directly to a base

where it can easily penetrate like

wood or gypsum board.

08

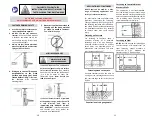

Center Punch Test

MUST WEAR EYE

PROTECTION WHILE

PERFORMING THIS TEST

1.

Always check the hardness of the

base where you want to fasten.

2.

Using a fastener as a center punch,

strike the fastener with a hammer

against the work surface and check

the results.

1.

Operators and bystanders must

always wear approved ear and eye

protection.

Failure to do so can

cause blindness or serious eye

injury from debris, and hearing loss

from exposure to constant or

repeated noise from the fastening

tool.

2.

Keep the work area clear of

unnecessary

materials

and

bystanders

that may interfere

with the safe operation of the

tool.

Operating tool in a congested

or disorderly area may affect the

ability to operate safely.

Center Punch Test Result

1.

The material is too hard for a

powder actuated fastening, if the

fastener point is flattened.

2.

The material is too soft, if the

fastener easily penetrates it.

3.

The material is too fragile, if the

material cracks or shatters.

4.

The material is suitable for powder

actuated fastening, if the fastener

causes a small indentation in the

material.

Selection of Loads and Safety

1.

Always make a fastening test after

ensuring that the base material is

suitable

to

determine

the

appropriate

power

level.

If

excessive power

is used,

the

fastener

may

pass

completely

through the work material, causing

death or severe injury to someone

who may be in the path of the

fastener.

2.

All operators must always select

the level of the loads by the power

level number

to avoid the use of

incorrect loading.

Safety at Work

3.

Never operate the tool when

explosive

or

inflammable

materials are close by.

Powder

loads may create sparks when fired

and could ignite these materials or

vapors.

4.

Always provide warnings within

50

’

of the area where fastening is

taking place:

“

CAUTION - Powder

Actuated Tool In

Use”

.

Failure to

warn others can result in serious

injury or death to them. Contact

your supervisor for this sign.

Powder actuated

tool in use

09

Содержание BP-27C

Страница 12: ...23 NOTES 22 NOTES ...