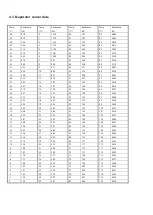

4.2.4

BLMI-900A (208-230V/60Hz)

content

Ambient

Temp

(

º

F/

º

C)

Water temp(

º

F/

º

C)

50

º

F/10

º

C

70

º

F/21

º

C

90

º

F/32

º

C

Approximate electric

consumption

[W] (Stable after 5 min)

70/21

1342

1248

1361

1251

1405

1253

80/27

1448

1340

1520

1354

1558

1355

90/32

1554

1427

1583

1433

1666

1440

100/38

1709

1539

1735

1543

1749

1547

Current consumption [A]

(Stable after 5 min)

70/21

6.2

5.8

6.3

5.8

6.5

5.8

80/27

6.7

6.2

7.0

6.3

7.2

6.3

90/32

7.2

6.6

7.3

6.6

7.7

6.7

100/38

7.9

7.1

8.0

7.1

7.9

7.1

Approximate water

consumption per 24hr

[gal/day, m^3/day)

70/21

125

0.47

124

0.47

122

0.46

80/27

116

0.44

112

0.43

111

0.42

90/32

108

0.41

97

0.37

96

0.36

100/38

94

0.36

92

0.35

90

0.34

Approximate electric

consumption

per 24hr [kWh/day]

70/21

29.8

30.5

31.0

80/27

32.5

33.4

33.8

90/32

34.6

34.7

36.2

100/38

38.0

38.3

38.9

Approximate ice production

per 24hr [Ib/day , kg/day]

70/21

890

404

868

394

853

387

80/27

807

366

794

360

784

356

90/32

759

344

706

320

703

319

100/38

666

302

647

293

629

285

Freezing cycle time [min]

70/21

20

20

21

80/27

22

23

23

90/32

24

27

26

100/38

28

29

29

Harvest cycle time[min]

70/21

3.3

2.8

2.7

80/27

2.8

2.5

2.4

90/32

2.4

2.3

2.2

100/38

2.2

2.2

2.2

Содержание BLMI-300A

Страница 1: ...SERVICE MANUAL BLMI 300A BLMI 500A BLMI 650A BLMI 900A Ver200626 ...

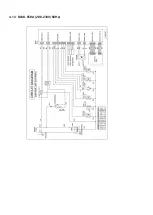

Страница 35: ...4 Circuit diagrams and technical data 4 1 Circuit diagrams 4 1 1 BLMI 300A 115V 60Hz ...

Страница 36: ...4 1 2 BLMI 500A 115V 60Hz ...

Страница 37: ...4 1 3 BLMI 650A 208 230V 60Hz ...

Страница 38: ...4 1 4 BLMI 900A 208 230V 60Hz ...