OPERATING INSTRUCTIONS

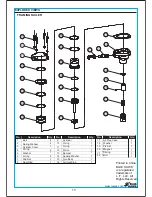

4. Air supply

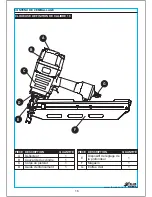

5. Loading fasteners and operating

When connecting air supply, always keep hands and body away from discharge area of tool.

A filter regulation-lubrication (not included) is required and should be located as close to the

Make sure the air pressure is set at the correct range of 80 - 120 PSI before using. Never

exceed 130 PSI.

tool as possible.

Not all components shown are included.

Place five or six drops of pneumatic tool oil (not included) into the air inlet. If you use an

automatic inlet oiler, check and add oil if necessary.

Check and replace any damaged or worn parts on the tool.

Make sure the magazine is empty of all fasteners and the hose has a rated work

pressure, then connect the tool to air compressor using a 3/4 in. ID hose.

Regulate the air pressure to obtain 5 - 8 bar depending on working demands and

characteristics of workpiece.

Before loading the fasteners, disconnect the tool from the air supply. Gripping the tool firmly,

pull the pusher back and engage the latch.

Insert a strip of fasteners keeping point down.

Orient and slide this strip of fasteners forward to the front of the magazine.

Release the latch and pusher. Slide the pusher against the nails.

Test the driving depth in a sample piece of wood before using. If the fasteners are being

driven too far or not far enough, adjust the regulator to provide less air pressure or more air

pressure.

Tool

Quick

Quick

Coupler

Quick

Coupler

Air Hose

Regulator

Air

Compressor

Connector

Quick

Oiler

Filter

Connector

4

8

Never operate tool unless safety nose is in contact with workpiece. Do not operate tool

without fasteners or damage to tool may result.

Never fire fasteners into air because fasteners may injure operator or others and damage to

tool may result.

R

www.lowes.com