9

INSTALLATION

Installing the Silencer

1. Inspect the condition of the silencer liner

and jacket prior to installing it onto the

nozzle. Make sure the silencer liner is

not damaged or cracked or has pieces

missing. Inspect the silencer liner wall

thickness at the exit of the silencer –

typically the silencing effect will reduce

if the silencer is excessively worn. The

silencer is excessively worn if the exit

diameter has worn per the following table:

Inspect the silencer jacket for damage.

If the silencer is damaged or excessively

worn do not continue to use the silencer.

2. Ensure the system pressure is isolated

before installing the silencer onto the

nozzle.

3. The nozzle has been designed to be used

with or without the silencer. If required,

remove the bump guard, and clean the

threads on the nozzle exit and the silencer

and make sure they are free of any grit or

debris.

4. The silencer is installed onto the nozzle by

screwing it onto the outlet end of the nozzle

as shown below.

Note:

there is no silencer washer.

5. Continue to screw the silencer onto the

nozzle until the nozzle reaches the end of

the silencer thread, then tighten the nozzle

until it is hand tight. Do not over-tighten the

nozzle in the nozzle holder or use any tools

to tighten the nozzle.

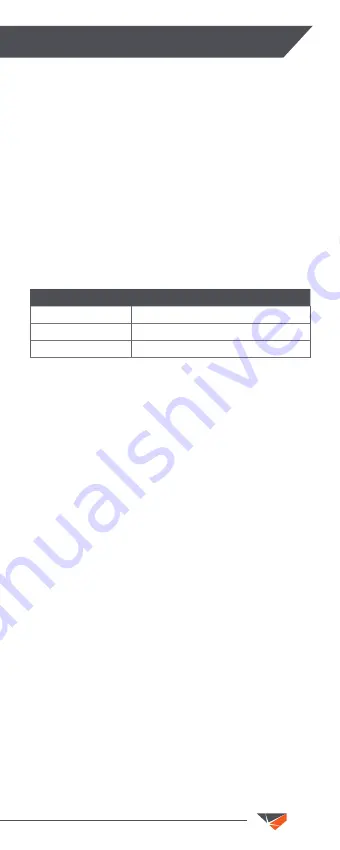

NOZZLE SIZE

EXCESSIVELY WORN DIAMETER

No. 6

27 mm (1.06 in)

No. 7

30 mm (1.18 in)

No. 8

34 mm (1.34 in)