110-A01: Page 13/14

TROUBLESHOOTING

NOTICE:

Maintenance shall be performed by qualified technicians only,

following the appropriate procedures and warnings as presented in this manual.

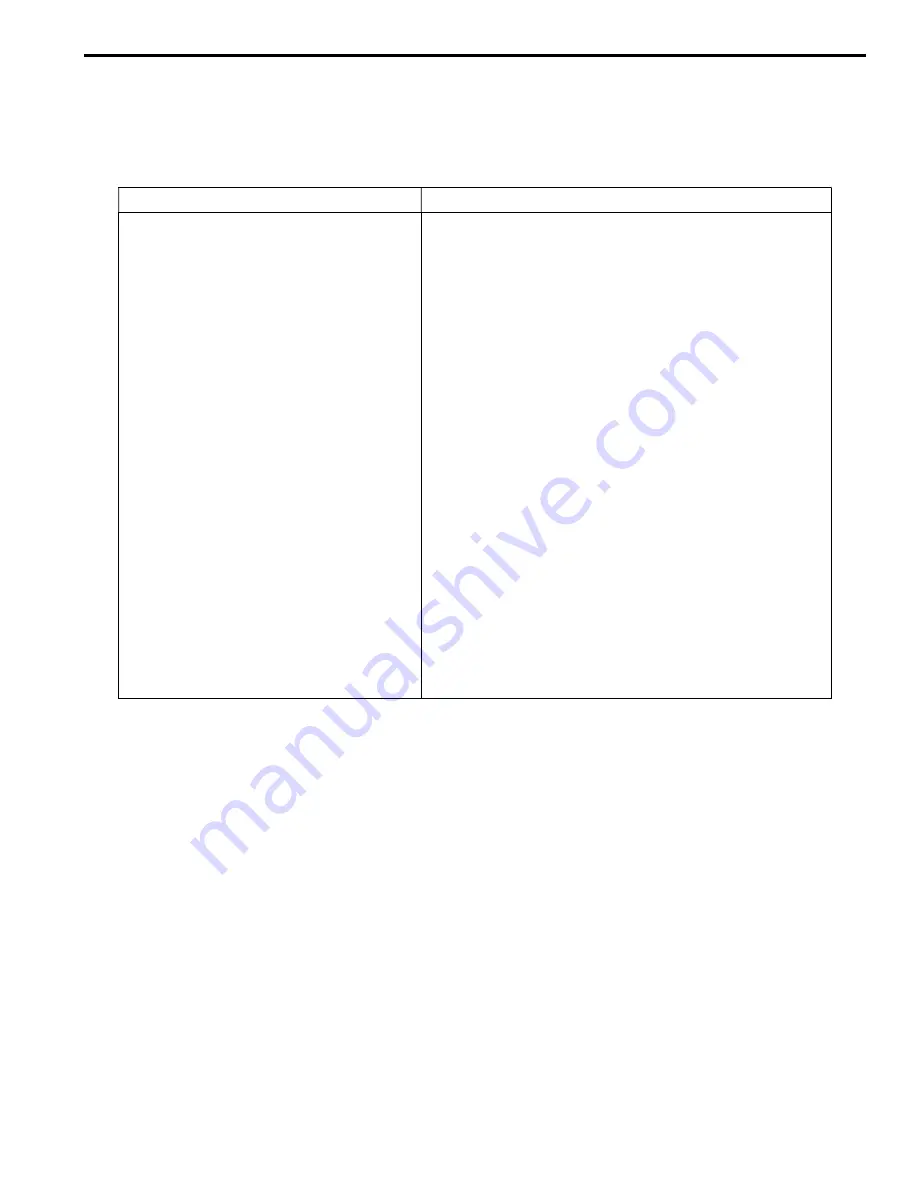

PROBLEM

CAUSE

Pump Not Priming

See causes 1 through 7

Reduced Capacity

See causes 1 , 2, 3, 6 through 10

Noisy

See causes 1, 6, 7, 8, 9, 11 through 14

Damaged Vanes

See causes 8, 11, 16 through 21

Broken Shaft

See causes 7, 11, 13, 16, 17&20

Motor Overload

See causes 9, 13, 17, 22 & 23

1. Suction/discharge valve incorrectly set.

2. Leaks in suction piping.

3. Incorrect rotation.

4. Broken shaft.

5. Pump vapor locked.

6. Incorrect pump speed.

7. Vanes damaged, worn or incorrectly installed.

8. Cavitation.

9. Damaged or worn pump or system components.

10. Excessive piping/system friction losses.

11. Relief valve incorrectly set, worn or damaged.

12. Operating against a closed discharge.

13. Shaft bent or misaligned.

14. Worn or damaged bearings.

15. Piping inadequately anchored.

16. Foreign objects entering the pump.

17. Viscosity too high

18. Excessive heat.

19. Worn or damaged push rods.

20. Hydraulic hammer - pressure spikes.

21. Incompatible fluid(s).

22. Inadequate horsepower.

23. Incorrect voltage, wiring, phase loss.