GENERAL INFORMATION

CB5A-021 page 3/24

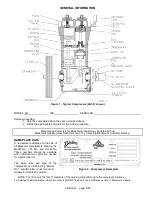

Figure 1 - Typical Compressor (LB361 shown)

MODEL: LB ID#: SERIAL NO:

Before proceeding:

1. Note the nameplate data in the space provided above.

2. Obtain the appropriate parts lists for the model in question.

Manuals and Parts Lists for Blackmer products may be obtained from

Blackmer's website (www.blackmer.com) or by contacting Blackmer's Customer Service.

NAMEPLATE DATA

A nameplate is attached to the side of

all Blackmer compressors showing the

Model No., I.D. No., and Serial No.

These numbers should be available

when information or parts are needed

for a particular unit.

The basic size and type of the

compressor is indicated by "Model

No." A suffix letter is used on most

models to indicate the version.

NOTE: The ID is only the first 11 elements of the catalog string referring to the compressor options.

For detailed ATEX Declaration information, refer to FORM 576 found in the Certification section of Blackmer’s website.

Figure 2 - Compressor Nameplate