◈

Information

This Installation Guide includes a brief outline of information necessary for product

installation. For more detailed installation information, please refer to the user manual in the

enclosed CD. The contents of the CD include the following.

1. Manual: User Manual, Code Chart, Control Commands

2. Drivers: Windows Drivers, OPOS Drivers

3. Utilities: a logo download tool and a virtual memory switch control tool

We at BIXOLON maintain ongoing efforts to enhance and upgrade the functions and quality

of all our products. In following, product specifications and/or user manual content may be

changed without prior notice.

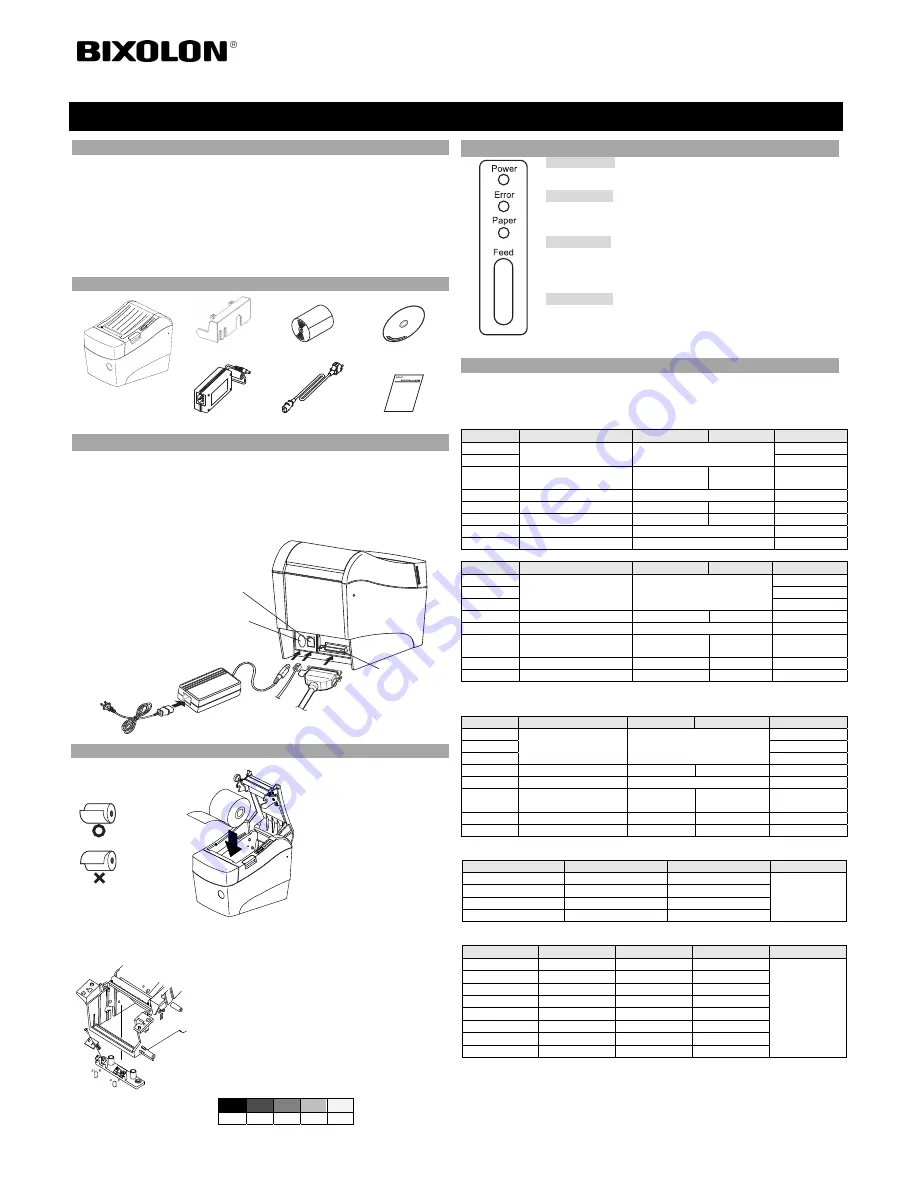

◈

Components

SRP-370/372

Cable Cover

Paper Roll

Procuct Installation CD

Procuct Installation CD

Procuct Installation CD

CD

AC/DC Adaptor

Power cord

Installation Guide

◈

Connecting the cables

1. Turn off the printer and the host ECR (host computer).

2. Plug the power cord into the Adaptor, and then plug the Adaptor into the power connector

of the printer.

3. Check the interface cable (Serial, Parallel, USB, or Ethernet), and connect the interface

connector cable accordingly.

4. Plug the drawer kick-out cable into the drawer kick-out connector on the printer.

※

Do not use an adapter that was not supplied with the printer.

◈

Installing the Paper Roll

1. Open the paper roll cover by

pressing the cover-open button.

2. Insert a new paper roll, making

sure to align it properly.

3. Pull out a small amount of paper,

and close the cover.

※

Note

When closing the cover, press down

on the center of the cover to ensure

that the paper is in contact with the

roller.

Printing quality may not be optimum

if recommended paper is not used.

(Refer to the User's Manual.)

※

Note : Adjusting the Paper Near-End Sensor

The paper near-end sensor performs the two functions of gauging

‘No Paper’ status as well as detecting black marks. In order to

gauge ‘No Paper’ status, the sensor must be in the “a” position as

shown in the picture. The factory default setting places the

sensor in this position. To detect black marks, the sensor must

be in the "b" position.

Black marks must have an optical density (O.D.) of at least 0.6 to

be safely detected.

As the black mark density of the paper can cause operating

errors, make sure to check it.

※

Note: O.D. Value Chart

1.4 0.9 0.6

0.3 0.2

◈

Using the Operation Panel

•

POWER (LED)

When turning on the power, a green LED will be lit.

•

ERROR (LED)

When an error occurs, a red LED will be lit.

(e.g. no paper, cover ajar, etc.)

•

PAPER (LED)

Red LED will be lit when the paper roll is running low. The LED blinks

when the printer is in self-test printing standby mode or macro execution

standby mode.

•

FEED (Button)

Press the FEED button once to discharge extra paper. Holding down the

FEED button will discharge paper continuously until the button is

released.

◈

Setting the DIP switches

Changing Dip Switch settings must be done when the printer is off. Any changes done while

the printer is on will not be processed.

1. Serial Interface

• DIP Switch 1

SW

Function

ON

OFF

Default

1-1

Baud Rate Selection

Refer to the following table 1

ON

1-2 ON

1-3 Handshaking

Software

(Xon/Xoff)

Hardware

(DTR/DSR)

OFF

1-4 Reserved

--

OFF

1-5 Auto

Cutter Disable

Enable

OFF

1-6

Paper

Two colors

Mono color

OFF

1-7 Reserved

--

OFF

1-8 Reserved

--

ON

• DIP Switch 2

SW

Function

ON

OFF

Default

2-1

Print Density

Refer to the following table 2

OFF

2-2 OFF

2-3 OFF

2-4 Historical

Control Enable Disable OFF

2-5 Reserved

--

OFF

2-6

Interface Condition

Selection

Memory

Switch

DIP Switch

OFF

2-7

Near End Sensor Status

Disable

Enable

OFF

2-8

Printing Width

2” Printing

3” Printing

OFF

2. Parallel / USB Interface

• DIP Switch 2

SW

Function

ON

OFF

Default

2-1

Print Density

Refer to the following table 2

OFF

2-2 OFF

2-3 OFF

2-4 Historical

Control Enable Disable

OFF

2-5 Reserved

--

OFF

2-6

Interface Condition

Selection

Memory

Switch

DIP Switch

OFF

2-7

Near End Sensor Status

Disable

Enable

OFF

2-8

Printing Width

2” Printing

3” Printing

OFF

• Table1 – Baud rate (bps) Selection

1-1

1-2

Transmission Speed

Default

OFF OFF 9600

115200

ON OFF 19200

OFF ON 38400

ON ON

115200

• Table 2 – Print Density Selection

2-1

2-2

2-3

Print Density

Default

ON ON ON 130%

100%

OFF ON ON 120%

ON OFF ON 110%

OFF OFF ON 105%

OFF OFF OFF 100%

ON OFF OFF 95%

OFF ON OFF 90%

ON ON OFF 80%

Printer Installation Guide

KN04-00017A (Rev.2.7)

THERMAL PRINTER SRP-370/372

Ver.2

Power cord

Drawer

kick-out

cable

Interface cable

(Serial/Parallel/USB/Ethernet

Adaptor

Drawer kick-out connector

Power connector

Interface

connector