7

5.5. REPLACEMENT OF LEAD SCREW

fig. 1

To replace the lead screw 3690-M pos. 9 fig. l:

► remove locking bolts 12 (pin) from the vice body 1,

► slip the moveable jaw 4 together with screw unit from the body,

► unscrew two screws fastening the cover 8 to the moveable jaw,

► remove the screw unit from the jaw and screw out from the holder 7,

► remove the retaining ring 14, which holds down the cover, spring and washer,

► install the cover, spring 15, washer 16 and retaining ring 14 on the new (repaired)

screw 3690-M3,

► screw in the screw unit into the holder and install in the moveable jaw,

► screw in two screws fastening the cover to the moveable jaw,

► slip the assembled moveable jaw together with screw onto guides in the vice body,

► insert locking bolts 12 into openings in vice body (fig. 2).

6. STRUCTURE OF THE HYDRAULIC SCREW

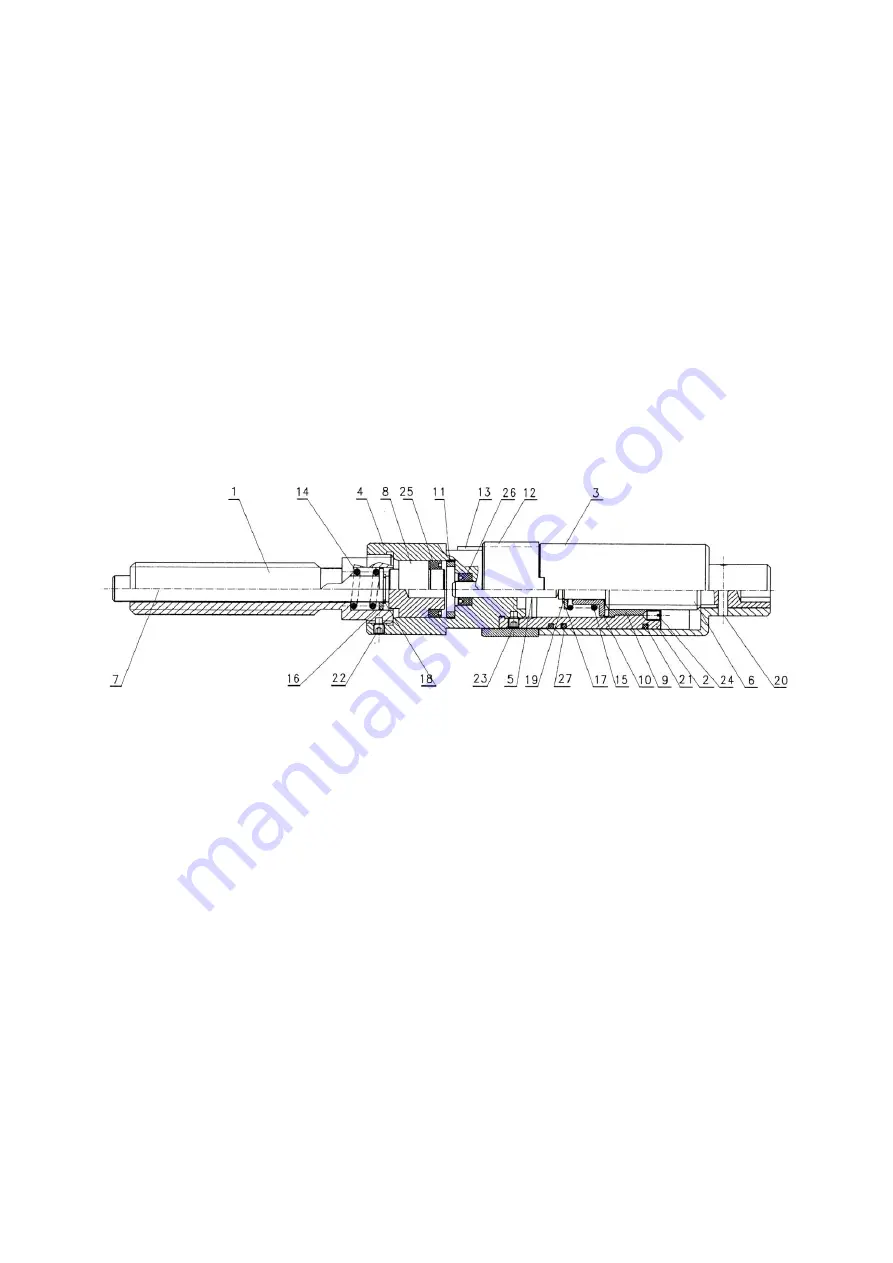

(fig.4)

Fig. 4. Structure of the screw 3690-M.

1. Fastening screw, 2. Body, 3. Housing, 4. Cylinder, 5. Plunger, 6. Clutch screw, 7. Mandrel, 8. Piston,

9. Screw plug, 10. Clutch disc, 11. Spacer, 12. Clutch sleeve, 13. Key, 14. Spring, 15. Spring, 16. Washer,

17. Washer, 18. Retaining ring, 19. Retaining ring, 20. Expansion pin, 21. Guide ring, 22. Pressure screw,

23. Pressure screw, 24. Pressure screw, 25. Sealing ring, 26. Sealing ring, 27. Sealing ring

6.1. OPERATIONAL PRINCIPLE

The workpiece is clamped with the mandrel 7, which pulls out from the fastening screw 1,

which co-operates directly with the holder in the vice or with threaded sleeve in the production

jig.

While manually turning (or with crank put into hexagonal screw socket) the knurled housing 3

of hydraulic screw we eliminate initially play between clamping appliance and workpiece, next,

after application of initial pressure, occurs disconnection of elements of claw clutch 9, 10 and

screwing of the screw 6 inwards.

Now activated is the hydraulic servo. Displacement of the screw 6 causes slipping of the

plunger 5 into the cylinder chamber 4. Because the liquid volume is constant, the pressure in

the cylinder grows. The force appearing on the piston 8 as a result of liquid pressure growth is

proportional to this growth. Because the surface of the piston is much bigger than the surface of