19

3.

With the mast cover removed, forks lowered and the key turned to the OFF position, thoroughly inspect the upper cylinder area, sling wheel

bracket, sling and transition switch. Never depress the transition switch unless the key switch is in the OFF position. Check the following:

• Mast Channels ................................................................................................................................................... Smooth and lightly lubricated

• Sling Wheel Bracket ............................................................................................................................................... All retaining rings in place

• Sling .......................................................................................................................................... Good condition – no tears or excessive wear

• Transition Switch

.......................................................................................................................................Good condition and bracket secure

• Upper Cylinder Area ............................................................................................................................ Return line in place – no fl uid leakage

Raise the forks to their maximum height and turn the key switch to the OFF position. Take care not to place your hands or feet under the

fork carriage unless it is securely blocked in the raised position. Check the following:

• Lower cylinder

......................................................................................................................... Hydraulic line and fi ttings secure – no leakage

• Constant Force Spring ............................................................................................................................................... Clean and free of debris

WARNING

DO NOT

attempt to remove the constant force spring. The constant force spring is heavily preloaded and will recoil

violently if released.

If the spring area contains debris, remove the debris with compressed air. Use caution, the sides of the spring may be sharp. Never push or pull

on the spring. If spring removal is required, contact your dealer or Bishamon for removal instructions.

Bishamon recommends replacing the constant force spring every two (2) years or fi ve thousand (5000) cycles.

Lower the forks and turn the key to the OFF position.

4.

Inspect the batteries and battery terminals. Ensure the terminals are clean and tight. Next, check the battery straps to ensure they are

tight and the batteries are not free to move.

5.

Check the level and appearance of the hydraulic oil. The oil level is visible through the reservoir. With the forks completely lowered, the

oil level should be 1 to 2 inches below the fi ller. Add hydraulic oil if required. Next, check the hydraulic oil for contamination. Using a dip

stick, remove a small amount of oil from the reservoir. The oil should appear light in color and be free of contamination. If the color has

darkened or if it feels gritty, the oil should be changed immediately. Refer to the following section for instructions on changing the hydraulic

oil.

6.

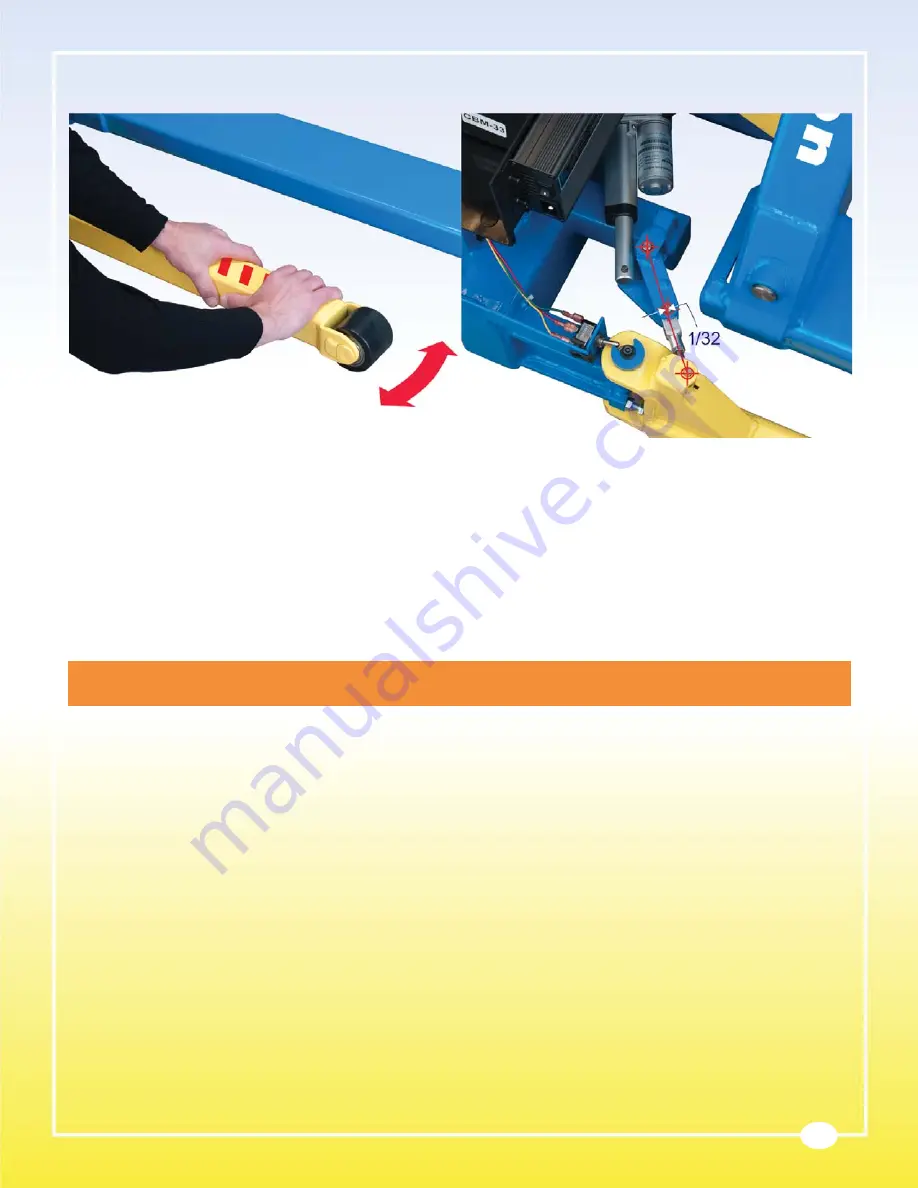

Grease the lever arm cam followers. To do so, raise the forks so that the yellow lever arms are at a convenient height. Using a grease gun

with a general purpose EP grease, lubricate both cam followers. Pump the gun slowly until grease protrudes from around the roller.

7.

Replace the lower battery cover, the upper console cover and the mast cover.

8.

Rotate the handle completely through its steering arc. It should move freely without binding. Pull the handle to its fully lowered position.

When released, the gas spring should be capable of returning the handle to its upright position. If required, replace the handle gas spring.

Figure 32 Outrigger Linkage

linkage should be locked and approximately 1/32 inch over-center. Check both outriggers. If either outrigger linkage required adjustment,

consult the factory for detailed adjustment instructions. DO NOT attempt to adjust the outrigger linkage assembly without a thorough

understanding of the adjustment procedure.