SPRAY TECHNIQUE

The first requirement for a good resultant

finish is the proper handling of the gun.

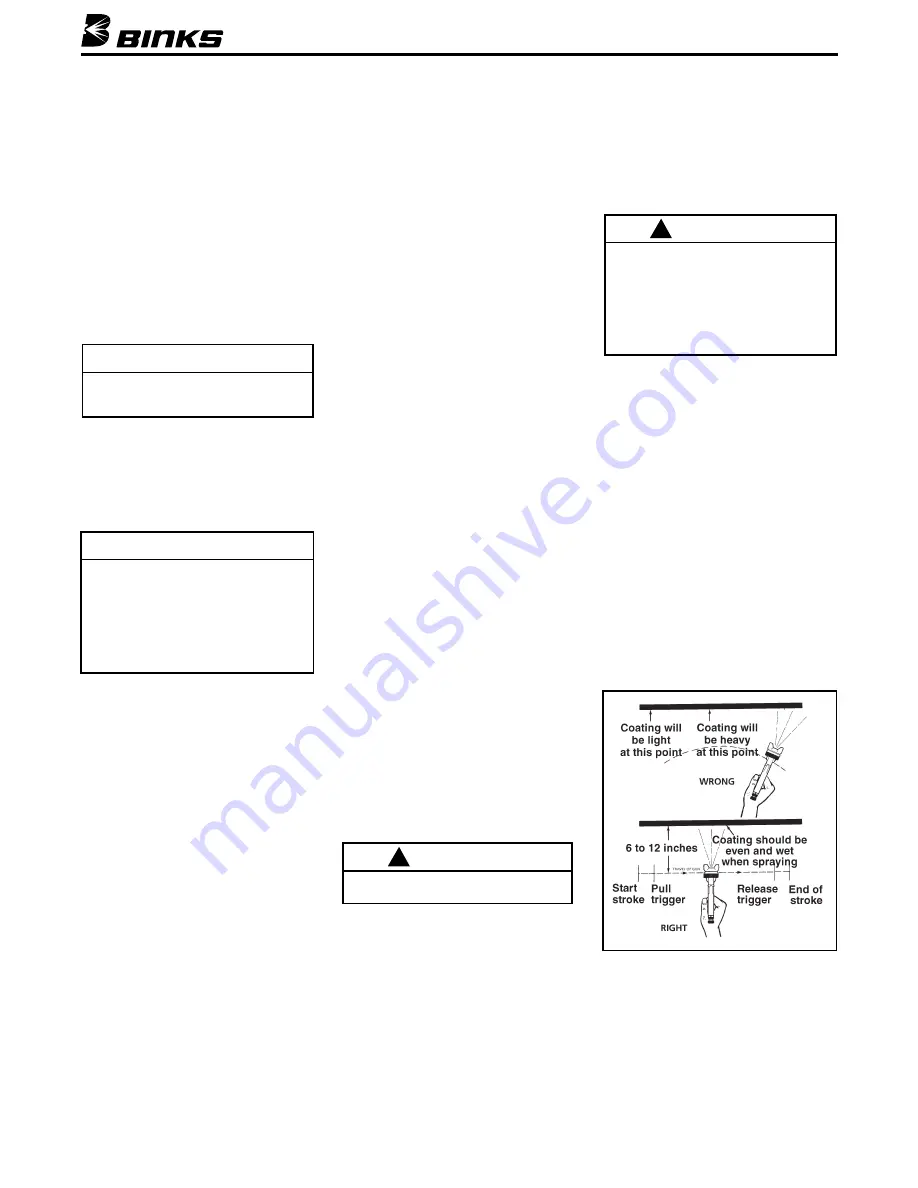

The gun should be held perpendicular

to the surface being covered and moved

parallel with it. The stroke should be

started before the trigger is pulled and the

trigger should be released before the

stroke is ended. This gives accurate

control of the gun and fluid.

The distance between gun and surface

should be 6 to 12 inches depending on

fluid and atomizing pressure. The fluid

deposited should always be even and wet.

Lap each stroke over the preceding stroke

to obtain a uniform finish.

GENERAL SPRAY INSTRUCTIONS

To reduce overspray and obtain maximum

efficiency, always spray with the lowest

possible fluid/air pressure that produces

an acceptable spray pattern.

For best results, use 3 to 6 psi fluid pres-

sure. Higher than 6 psi fluid pressure may

be required for heavy-bodied materials.

Low fluid pressures will produce a nar-

rower than normal spray pattern.

Generally use 30-35 psi air at gun inlet

(see page 6). Unusually heavy, difficult to

atomize fluids may require up to 50 psi

air at gun inlet.

CONTROLLING THE FAN SPRAY

The fan spray is controlled by means of

the side port control assembly (7).

Turning this control clockwise until it is

closed will give a round spray; turning it

counterclockwise will widen the spray

into a fan shape. The fan spray can be

turned anywhere through 360 ° by posi-

tioning the air nozzle (2) relative to the

gun. To accomplish this, loosen retaining

ring (1), position nozzle (2), then tighten

retaining ring (1).

CONTROLLING THE FLUID FLOW

When used with a pressure assisted cup,

an increase in air pressure will increase

the rate of flow. When fed from a pres-

sure supply, an increase in the fluid pres-

sure will increase the rate of flow. Correct

fluid nozzle size should be selected for

correct fluid flow rate. The fluid control

knob (19) may be used to restrict the (3)

fluid nozzle opening and reduce the fluid

flow as necessary.

AIR NOZZLE, FLUID NOZZLE,

NEEDLE ASSEMBLY

1. All nozzles and needles are precision

made. They should be handled with

care.

2. Except as described in “ADJUSTING

THE NEEDLE ASSEMBLY”, do not

make any alterations in the gun. To do

so could cause finishing difficulties.

3. To clean nozzles, soak them in solvent

to dissolve any dried material, then

blow them clean with air.

4. Do not probe any of the holes in the

nozzles with metal instruments. If

probing is necessary, use only a tool

that is softer than brass.

ADJUSTING THE NEEDLE

ASSEMBLY (16)

1. Remove the fluid control knob (19)

and the blue spring (14).

2. Pull the needle assembly out approxi-

matley 1-1/4 inches.

3. Loosen the needle cap (18).

4. Screw the needle assembly locknut

(17) out for more trigger movement,

in for less trigger movement.

5. Adjust the needle assembly so that

when the trigger (23) moves, the spin-

dle assembly (13) moves 1/16 to 3/32

of an inch before the needle assembly

moves.

6. Tighten the needle cap.

TROUBLESHOOTING

Faulty Spray

A faulty spray pattern is often caused by

improper cleaning resulting in dried mate-

rials around the fluid nozzle tip or in the

air nozzle. Soak these parts in thinners to

soften the dried material and remove with

a brush or cloth.

Intermittent Spray

If the spray flutters, it is caused by one

of the following faults:

1. Insufficient fluids available. Check

supply and replenish if necessary.

2. Pressure vent tube from gun body

to pressure assist cup is loose or

leaking.

3. Check valve in pressure assist cup

is stuck or blocked.

4. Pressure assist cup cover not suffi-

ciently tight or cover gasket defective.

5. Insufficient fluid pressure from stan-

dard pressure pots.

7

OPERATING THE MACH 1SL

HVLP SPRAY GUN

CAUTION

NEVER USE METAL INSTRUMENTS TO

CLEAN THE AIR OR FLUID NOZZLES. THESE

PARTS ARE CAREFULLY MACHINED AND

ANY DAMAGE TO THEM WILL CAUSE

FAULTY SPRAY. If either the air nozzle (2)

or fluid nozzle (3) are damaged, these

parts must be replaced before perfect

spray can be obtained.

!

NOTE

To reduce overspray and obtain maximum

efficiency always spray with the lowest

possible atomizing air pressure.

NOTE

Excessive atomizing air pressures can

increase overspray, reduce transfer

efficiency, and with some materials,

result in poor finish quality from dry

spray. Atomizing air pressures should

not exceed 10 psi. See table on page 6,

diagram on page 2 and regulatory note

on page 8.

CAUTION

Overtightening may damage the threads

and make future adjustments difficult.

!