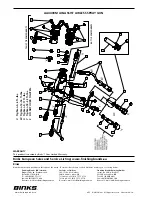

7

fig. 17

fig. 19

fig. 21

fig. 20

fig. 22

REaSonS to SERVIcE aIR VaLVE:

A) Air valve not functioning correctly (may need cleaning).

B) Routine maintenance.

C) Air leaks (advise replacement, see p8)

1. Remove trigger and fluid tube assembly. (See fig 13 & 14)

2. Unscrew air valve using 14 mm wrench. (See fig 15)

3. Remove air valve by gripping stem. (See fig 16)

4. Remove spring with spring pad. (See fig 17)

5. DO nOT REMOVE REAR SEAL FROM GUn BODY.

(See fig 18)

6. DO nOT REMOVE PLASTIC CAGE FROM AIR VALVE

BODY AS THIS MAY DAMAGE THE CAGE. (See fig 19)

7. CLEAn

a. Remove all paint build up. (See fig 20)

b. The 4 poppet holes must be clear. (See fig 21)

c. Stem must be free to float in poppet. (See fig 22)

d. Stem must slide through cage bore with slight resistance

(due to seal).

e. Rear seal must look clean and in position in the bore.

(See fig 18)

f. If any of the above cannot be rectified, replace the air valve.

(See Replacing Air Valve p8)

8. Replace spring ensuring the end with the plastic bearing pad

goes in first. (See fig 17)

9. Insert air valve assembly into gun and carefully feed over the

spring and through the rear seal. (See fig 23)

10. Tighten air valve assembly using fingers first, and then tighten

with 14mm wrench. Torque from 18 to 22 ft.-lbs. (See fig 24)

11. Replace the fluid tube and trigger. (See figs 14 & 13)

12. If there is an air leak through the gun, the air valve may need

replacing. (See Replacing Air Valve p8)

SERVIcInG aIR VaLVE

CAutIon

always ensure that all fluid and air pressure to the gun has been dis-

charged before proceeding with any repairs.

!

fig. 18

fig. 16

fig. 23

fig. 15

fig. 24

fig. 13

fig. 14