Page 9 of 12

BA_2009_2_GB_DR4

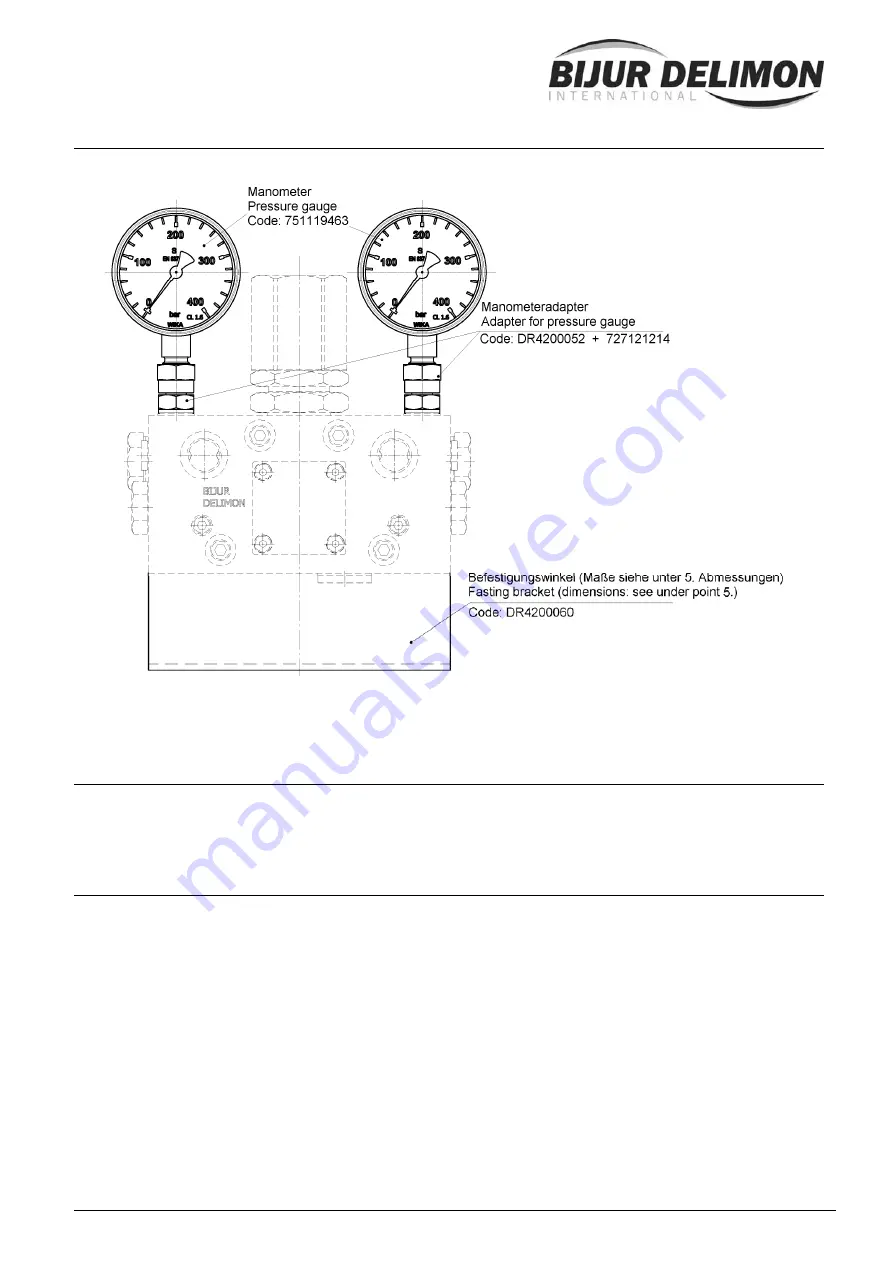

E. ACCESSORIES

(continued)

2 x pressure gauges (with adaptor) and mounting brackets (for fixing onto the basic frame)

3. Application

The DR4 is an hydraulically operated directional control valve for use with dualine or non-return systems.

4.

Principle of operation

The reversing valve’s switching pressure depends on the spring pressure, which can be set for

installation. After the activation of all dual-line metering valves in the lubricating system, pressure is built

up against a guide piston, which in turn acts on a rocker arm. If the force acting on the rocker arm is

equal to the spring force, it moves into the other end position. This directs a control current towards one

end of the piston, which determines the direction of flow. The piston moves, thereby freeing at the other

end the passage to the tank. Accordingly the pump’s delivery flow is directed into the opposite line and

the pressure is taken off the originally pressurised line back to the tank.

An electric switch, which is activated by means of a pin attached to the control piston in the direction of

flow, is mounted on the reversing valve. When the switch is activated by the pin, either to open or close it,

a signal is sent to the control to either stop the pump or start a switching interval.

The diagram and the details on pages 4 clarify the mode of operation. The following mode of operation is

available for use in dual-line lubrication systems.

On the DR4 valve (non-return system), the two pipelines do not return to the reversing valve but the

reversal pressure is sufficient for the operation of all the measuring valves.