Electronic control p.c.b.

22

9.6

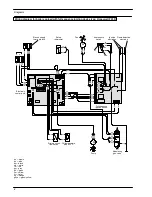

Setting jumpers

Two setting jumpers are fitted on the Electronic control

p.c.b.

Refer to Fig. 35 for the position of the jumpers when the

Electronic control p.c.b. is fitted on a M90D.24S or

M90D.28S boiler.

Refer to Fig. 36 when the Electronic control p.c.b. is

fitted on a M90D.24SR or M90D.28SR boiler.

The numbers refer to the marking printed on the circuit

board.

1 2 3 4 5 6 7 8 9

Fig. 35

1 2 3 4 5 6 7 8 9

Fig. 36

9.7

Ignition gas pressure adjustment

By using the device ”10” (Fig. 28) marked “ACC.” on

the Electronic control p.c.b., it is possible to adjust the

gas pressure at the injectors in the ignition phase.

This pressure is maintained at the injectors until ignition

occurs (ionization signal from the full sequence ignition

device).

To carry out the adjustment move the function selector

3 to the OFF position (Fig. 33) and use the adjustment

device ”10” (ACC).

Adjust the gas pressure at the injectors to the value indi-

cated in the tables of the User/Installation manual

(

Technical information

section,

Gas pressures at the

burner

table).

By rotating the device clockwise the pressure in-

creases.

Check the regular ignition of the burner by turning the

boiler on and off repeatedly.

After the adjustment operations bring the selector 3

back to the normal position (ON).

9.8

Max c.h. power adjustment

By using device 11 (Fig. 28) marked “RISC.” on the

Electronic control p.c.b., you can limit the maximum

useful output delivered during the c.h. operating mode.

This adjustment does not influence the maximum use-

ful output delivered during the d.h.w. operating mode.

By rotating the device clockwise the pressure in-

creases.

9.9

Checks

n

Check that the fuse is complete

If the Electronic control p.c.b. does not supply any de-

vice (pump, fan, etc.) check that the fuse 13 (Fig. 28) is

complete.

If the fuse has blown replace it with one that has the

same characteristics after having identified the reason

for failure.

n

Check the setting jumpers position

Two setting jumpers must be fitted on the Electronic

control p.c.b. as shown in Fig. 35 and Fig. 36.

9.10

Removal of the electronic control p.c.b

Warning: isolate the boiler from the mains

electricity supply before removing any

covering or component.

1

Gain access to the parts located inside the con-

trol panel as explained in the section 2.3 of this

manual.

2

Remove all the wiring connected to the Electronic

control p.c.b..

To disconnect the connectors J1, J2 and J3 (12,

2 and 1 in Fig. 28) delicately flex the hook present

on one side of each socket.

3

Remove the spindles of the c.h. and d.h.w. tem-

perature adjustment knobs by delicately pulling

them with pliers in the direction shown by the

arrow in Fig. 37.

Fig. 37

4

Unscrew the four screws that hold the Electronic

control p.c.b. on to the control panel.

5

Remove it by lifting its rear edge and freeing it

from any of the wiring.

6

Re---assemble the Electronic control p.c.b. fol-

lowing the removal procedures in the reverse

order.

Important

When re---assembling the Electronic control p.c.b.:

7

Fit the p.c.b. into the control panel by first insert-

ing the front lower edge under the control knob

shafts. Lower the rear edge and ensure that no

wiring is trapped beneath.

8

Insert the spindles in the control panel knobs un-

till the notch

A

(Fig. 38) reaches the potentio-

meter edge. It is not necessary to force them in

the knob.

9

While tightening the screws that fix the Electronic

control p.c.b. on the control panel, keep the

Содержание RIVA PLUS M90S.24S

Страница 2: ......

Страница 43: ...Short spare parts list 41 1 2 6 4 5 7 3 8 15 18 12 13 20 21 22 23 25 26 14 16 24 17 19 9 10 11 9...

Страница 44: ...1796209146 17962 0914 6 3804 44A4 UK...