15

40 h 8 h 40 h 16 h 40 h 8 h 40 h

Fig. 10

5.7 Lubrication

Make sure that the motor is switched off and all moving parts are secured before

peforming any maintenance/repair work on the machine. Improper lubrication

may cause dangerous contamination of the sliding parts and consequent dama-

ges for which the manufacturer holds no responsibility!

The winch is equipped with self-lubricating bearings that require no

further lubrication or maintenance.

Maintenance is mainly required on the engagement/locking mecha-

nism (Pos. 13 - Fig. 7) that needs periodical

checkup. Clean all metal surfaces preferably with WD-Spray like

agents in order to:

• increase lubricant efficacy and

• inhibit formation of humidity, condense water and ice on the leve-

rage and the control rods and therefore prevent consequent functional

troubles.

Lubricate the housing of the upper block every 40 hours.

Provide regular maintenance of the drive chain removing any eventual

residual dirt and slightly greasing it. Use grease suitable for high tem-

perature (it should not melt as common low-price grease) in order to

prevent grease contamination of the sliding clutch surfaces.

Strictly use special spray lubricant for link chains.

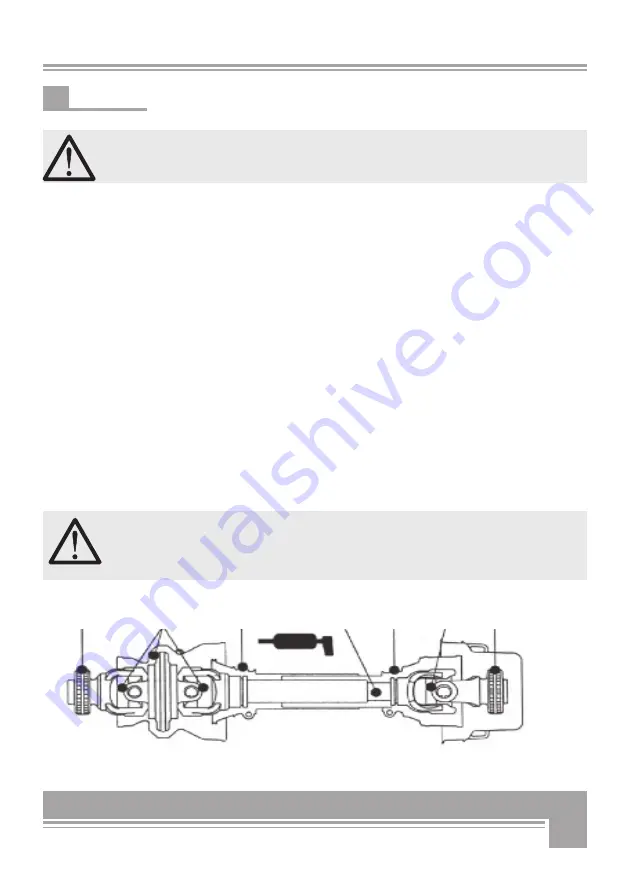

Provide PTO shaft lubrication in accordance with the instructions of

the manufacturer (Fig. 10).

Make sure to avoid contamination of the clutch lining with gre-

ase as this may lead to a significat loss of the pull force and

to early wear of the clutch plates that will then need to be re-

placed!

Содержание FSW 3.5 M

Страница 24: ...24 12 EXPLODED DRAWING FSW 3 5 M Part 1...

Страница 25: ...25 Part 2...

Страница 29: ...29...

Страница 30: ...30...

Страница 31: ...31...