Form Title:

Document #:

INSTALLATION AND MAINTENANCE MANUAL

MM-AD001

(Form: DEF-006A-1)

Revision:

4

Document Title:

Date:

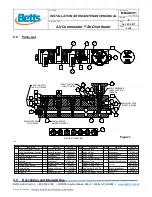

Air Commander™ Air Distributor

Oct. 23, 2017

Page:

8 of 8

Betts Industries Inc.

▪

814·723·1250

▪

1800 Pennsylvania Ave. West

▪

Warren, PA 16365

▪

www.BettsInd.com

Print Date: 10/23/2017

This form is considered uncontrolled 24 hrs. after print date.

8.0

Trouble Shooting Guide

Problem

Potential Cause

Potential Solution

Valve drifts closed

Leak in air system

Check fittings and air lines for damage

or leaking.

Check for leaks in toggle. See section

6.1 and replace O-rings (2).

Check for leaks in wink. See section

6.2 and replace O-rings (2).

Check for leaks in master control. See

section 6.3 and replace O-rings (2).

System will not stay

charged

Master control knob is

damaged and will not stay

at charged position

See section 6.3 and replace master

control assembly (1).

Master control knob

will not pull up

Master control assembly (1)

detent spring has damaged

button holder.

See section 6.3 and replace master

control assembly (1).

System will not

exhaust when toggle

is switched to the

CLOSED position

Toggle is clogged or not

operating correctly.

See section 6.1 and replace O-rings

(2).

System will not

exhaust when master

control knob is in

closed position

O-rings (2) on master

control assembly (1) and/or

manifold (5) are damaged.

See section 6.3 and replace O-rings

(2).

Wink does not shift to

red when system is

charged

Wink O-ring (13) is

damaged

See section 6.2 and replace wink O-

ring (13)

Wink spring (14) or wink

piston (7) are damaged.

See section 6.2 and replace wink

piston (7) and/or wink spring (14).

Air is leaking out of

Master Control Knob

O-rings on Master control

piston are damaged or

missing

See section 6.3 and replace O-rings

(2).

Master control knob

will not stay down

when pushed into the

exhaust position

Breather plug is plugged off

and not exhausting air

Replace breather plug.