Form Title:

Document #:

INSTALLATION AND MAINTENANCE MANUAL

MM-AD001

(Form: DEF-006A-1)

Revision:

4

Document Title:

Date:

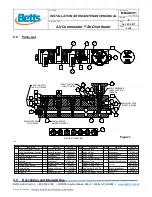

Air Commander™ Air Distributor

Oct. 23, 2017

Page:

2 of 8

Betts Industries Inc.

▪

814·723·1250

▪

1800 Pennsylvania Ave. West

▪

Warren, PA 16365

▪

www.BettsInd.com

Print Date: 10/23/2017

This form is considered uncontrolled 24 hrs. after print date.

1.0

General

1.1

It is strongly recommended that this entire manual be read prior to any operation,

disassembly, or assembly of this equipment.

1.2

Betts Industries, Inc. provides this manual as a guideline for reference only and assumes

no responsibility for personal or property damage that may occur in conjunction with this

manual. Betts Industries, Inc. cannot be held responsible for incorrect installation,

operation or maintenance of product.

1.3

Betts Industries, Inc. recommends all equipment be placed on a regular maintenance

schedule that includes the routine replacement of seals and gaskets and visual inspection

for leaks and corrosion. The end user must make their own determination and set their

own schedule based upon use and environment. In some cases, regulations may dictate

the minimum testing frequency of items. Make sure operators are aware of all applicable

codes.

1.4

Only trained personnel should attempt to perform maintenance on this equipment.

1.5

As with any maintenance work, proper safety gear and procedures must be used at all

times. A list of hazards may include but are not limited to contents under pressure, loaded

springs, residual product, flammable liquid and vapors, pinch points.

1.6

Safety alert symbols are used to alert operator to potential personal injury hazards. These

symbols are per ANSI Z535.5 and are listed below. Operator MUST obey all instructions

that follow a safety symbol.

Alerts will be used to indicate known safety concerns. Additional concerns are possible

and should be identified and avoided by the operator.

Indicates an imminently hazardous situation which, if

not avoided,

will result

in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided,

could result

in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided,

may result

in minor or moderate injury. It

may also be used to alert against unsafe practices.

1.7

Product Warranty shall be void if product is subject to misapplication, misuse, neglect,

alteration or damage.

1.8

Specific design details described in this document are for reference only and are subject

to change without notice. See Betts Industries, Inc. web page for the most recent revision

to this document.

www.bettsind.com

1.9

For additional questions or more detailed technical assistance, contact the Betts Industries,

Inc. Sales or Engineering Department at (814)723-1250.