Form Title:

Document #:

INSTALLATION AND MAINTENANCE MANUAL

MM-AD001

(Form: DEF-006A-1)

Revision:

4

Document Title:

Date:

Air Commander™ Air Distributor

Oct. 23, 2017

Page:

7 of 8

Betts Industries Inc.

▪

814·723·1250

▪

1800 Pennsylvania Ave. West

▪

Warren, PA 16365

▪

www.BettsInd.com

Print Date: 10/23/2017

This form is considered uncontrolled 24 hrs. after print date.

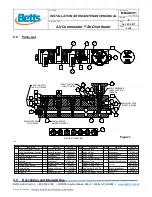

7.2

To repair/rebuild wink

:

7.2.1 Disconnect from air supply and relieve all pressure

prior to disassembly.

7.2.2 Remove 3 cap screws (18) wink piston (14) and

wink spring (7).

7.2.3 Inspect wink piston (14) for damage and be

sure red color is still intact, replace if necessary.

7.2.4 Remove wink O-ring (13) and replace.

7.2.5 Remove manifold O-ring (4) and replace.

7.2.6 Apply low temperature lubricant to wink

piston (14) in the red area, reassemble and

replace cap screws (18) and torque to

approximately 10-16 in-lbs

.

7.3

To repair/rebuild master control

:

7.3.1 Disconnect from air supply and relieve all

pressure prior to disassembly.

7.3.2 Pull up on master control knob (1) and remove master control

assembly (1) by unthreading from master control block (3).

7.3.3 Remove O-rings (2) from master control piston and replace.

7.3.4 Remove cap screws (18) from master control

block (3).

7.3.5 Remove O-ring (2) from manifold (5) and manifold

O-ring (7) and replace.

7.3.6

Reassemble master control block (3) and cap screws

(18) and torque to approximately 10-16 in-lbs

.

7.3.7

Replace O-ring (13) (see EB-1-17) and

apply low temperature lubricant to master

control piston O-rings (2) and removable

thread lock to threads of button holder and

reassemble master control assembly (1)

and torque to approximately 25-30 in-lbs.

SEE TROUBLE SHOOTING GUIDE ON PAGE 9

18

7

4

14

13

13

2

1

5

18

4

3

2