21.12.98

Operating manual

04_GB

ACP 3000 — 0.37–15.0

53

Berges electronic

•

D–51709 Marienheide-Rodt

•

Tel. 02264/17-0

•

Fax 02264/17126

The PI Controller operates within the limits set by parameter

A1-FCORR

, the value of which

establishes the frequency band across which the value of the integrator and the output of

the PI Controller may vary. If Feed-Forward is active, the output of the PI Controller is the

reference frequency

12-FOUT

±

A1-FCORR

, and the integrator's value is ±

A1-FCORR

.

Note that the final output of the PI Controller cannot be less than 0.00 Hz nor greater than

400.00 Hz.

The output of the PI Controller is sent to the ASIC after the proper frequency conversion.

The controller works in one direction of rotation which must be set by FWD and REV com-

mands. A change in direction while the controller is active yields unpredictable results.

The PI controller is limited in its application by the minimum resolution available through the

feedback terminal. Since the feedback terminal voltage is scaled through an 8-bit analog-

to-digital converter, the reaction of the PI loop is reduced.

For example, if the inverter is set to run from 0.00 to 60.00 Hz and the feedback is coming

from a tachometer rated at 50 V/1000 rpm and conditioned to be between 0–10 V with 2000

RPM being full scale, then the minimum change that the 8-bit A/D converter can register is

8 rpm. This means that, worst case, the speed can drop by 8 rpm when a load is applied,

but typical accuracy is ±2%.

Input CTS or a STOP command (or inputs FWD and REV active at the same time) stops

the inverter and resets the integrator part (sIPart) of the PI Controller when the value of

12-

FOUT

falls below 0.10 Hz.

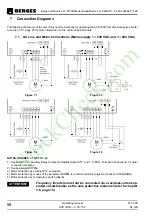

6.3

Reference and Feedback Inputs

A.

Configuration of Inputs

The PI reference value is input from either the keypad or the VIN2 terminal. The PI feedback

value is input from the VIN1 terminal. An error signal is calculated by the microprocessor

which adjusts the speed of the inverter within a range limited by the

A1-FCORR

parameter.

The PI feedback input (VIN1) is selectable through J20 as 0 to5 VDC, 0-10 VDC, 0 to 20

mA, or 4 to 20 mA. The PI reference input (VIN2) is selectable through J20 as 0 to 5 VDC

or 0 to 10 VDC.

Parameter

24-FSEL

is used to set the feedback input to be direct, inverted, or a 20% offset

from the minimum. This parameter must also be set to 16, 17, 18, or 19 to use VIN2 as the

reference input. Enabling the PI Controller without properly setting

24-FSEL

could result in

the use of a combination of VIN1 and VIN2 as the reference signal which will give unpre-

dictable results.

B.

Scaling the Feedback Input

The feedback input (VIN1) is scaled between 0.00 Hz and 1.125 times FMAX. For example,

if VIN1 is set to “direct” and FMAX is 60.00 Hz, then a full scale feedback signal will corre-

spond to 67.50 Hz.

This feedback input can also be scaled, via

B5-KIN

, from 0 to 255 which corresponds to a

range of 0 to 1.99. For example, if B5-KIN = 64, then a full scale feedback signal would cor-

respond to 33.75 Hz.

The function of scaling is to compensate the input for conditioning difficulties of the feed-

back signal. For instance, if the feedback is from an analog tachometer that gives a 50 V /

1000 rpm signal and the inverter is set up to have an FMAX of 60.0 Hz (which means that

VIN1 needs to read a signal of 67.5 Hz), then the maximum voltage from the tachometer

will be 101.25 V.

StockCheck.com

Содержание ACP micro 3000

Страница 1: ...Operating manual 0 37 15 kW S t o c k C h e c k c o m ...

Страница 2: ...S t o c k C h e c k c o m ...

Страница 75: ...S t o c k C h e c k c o m ...