ENGLISH

14

MySMART

15

MySMART C.S.I.

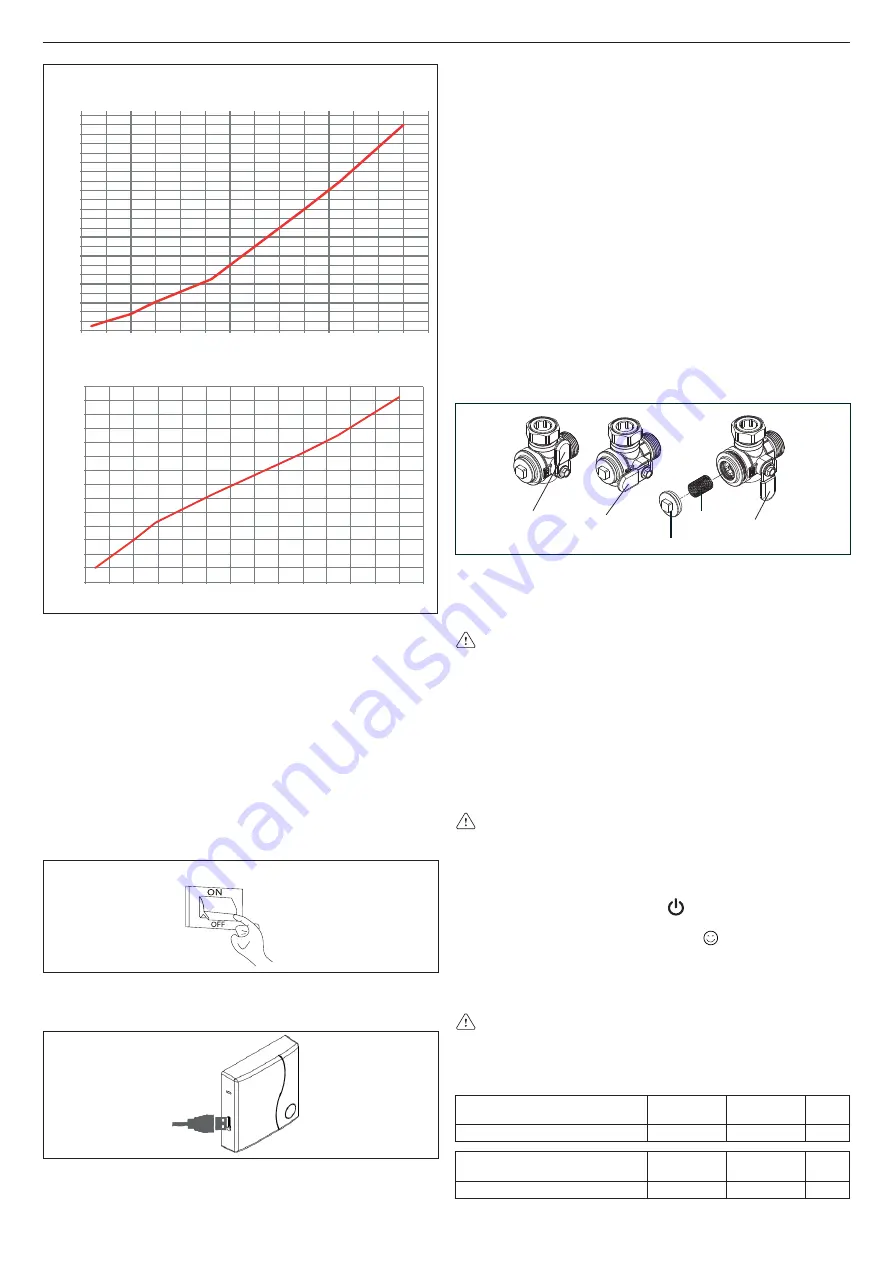

CO s.a. curve (Qnheating)

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

HTG curve (Qnheating)

Fan rotations (rpm)

Heat output (kW)

CO emissions s.a. (p.p.m.)

Heat output (kW)

800

1200

1600

2000

2400

2800

3200

3600

4000

4400

4800

5200

5600

6000

6400

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

5 - MAINTENANCE

To ensure product characteristics and efficiency remain intact and

to comply with prescriptions of current regulations, it is necessary to

render the appliance to systematic checks at regular intervals.

When carrying out maintenance work, observe the instructions given

in chapter 1 “Warnings and safety”.

Turn off the appliance before carrying out work or maintenance of

structures near the flue discharge connections and/or fume dis-

charge devices and their accessories. Once work is completed, a

qualified technician must check the efficiency of the appliance.

IMPORTANT:

before undertaking any maintenance or cleaning op-

erations, use the switch of the appliance itself and the system to in-

terrupt the electrical supply and close the gas supply using the tap

on the boiler.

It is also OBLIGATORY

to disconnect the cable connecting the WiFi

Box and the boiler

- return power to the boiler

- interrupt the vent cycle as described in the section “4.2 Appliance

ignition” on page 10.

5.1 Routine maintenance

This normally means the following tasks:

- removing any oxidation from the burner;

- removing any scale from the heat exchangers fume side;

- checking and cleaning the drainage pipes;

- checking the external appearance of the boiler;

- checking the ignition, switch-off and operation of the appliance, in

both domestic water mode and heating mode;

- checking the seal on the gas and water couplings and pipes;

- checking the gas consumption at maximum and minimum output;

- checking the position of the ignition-flame detection glowplug;

- check the “no gas” safety system;

- check operation of the check valve if it is installed (see section 3.12

“Installation on collective flues in positive pressure”).

- cleaning the filter inside the heating return line tap. Follow the in-

structions below:

- set the lever to “filter cleaning“

- unscrew plug

A

- remove the filter

B

and clean it

- remove any dirt in the filter chamber

- put back the filter

- put back the plug

A

- set the lever to the opening position

opening

position

closing

position

filter cleaning

position

A

B

-

Do not clean

the appliance or its parts with easily inflammable

substances (e.g. benzine, alcohol, etc.).

- Do not clean panels, painted parts and plastic parts with paint

thinner. Panel cleaning must be carried out only with soapy water.

After routine and extraordinary maintenance operations have

been carried out, fill the siphon, following the instructions in the

section “Preliminary cheks”.

5.2

Extraordinary maintenance

These tasks restore appliance operation in accordance with the

design and regulations - e.g. following the repair of an accidental

fault.

This normally means:

- replacement

- repair

- overhaul of components.

These tasks require special means, equipment and tools.

During the initial installation phase, or in the event of extraordinary

maintenance, you are advised to activate the procedure to

discharge air from the heating circuit and boiler (see section 3.4).

5.3

Checking the combustion parameters

MySMART C.S.I.:

- Position the function selector on to switch off the boiler (fig.

48)

- Turn the DHW temperature selector on (fig. 48).

Wait until the ignition of the burner (about 6 seconds). The display

shows “ACO”, the boiler operates at full power heating.

- Remove the screw

C

and the cover

E

on the air box (fig. 49).

- Insert the probes of the analyzer in the positions provided on the

air box.

Th

e flue gas analysis probe must be fully inserted as far

as possible.

- Check that the CO

2

values match those given in the table, if the

value shown is different, change it as indicated in the chapter

entitled “Gas valve calibration”.

MAXIMUM CO

2

METHANE

GAS (G20)

LIQUID GAS

(G31)

28 C.S.I.

9,0

10,0

%

MINIMUM CO

2

METHANE

GAS (G20)

LIQUID GAS

(G31)

28 C.S.I.

9,0

10,0

%

Содержание 20109808

Страница 103: ......