29

29

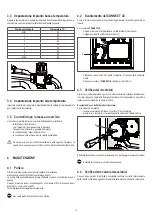

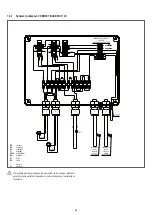

3.3 Setting the low temperature system

Set the low temperature system delivery temperature by manually adjusting the mixing

valve and referring to the following table.

Knob position

Temperature (°C)

MIN

20

1

25

2

30

3

35

4

40

5

45

6

50

7

55

MAX

60

3 4 5 6

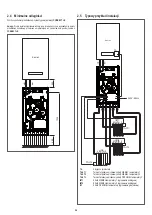

3.4 Setting the high temperature system

Set the heating temperature selector of the boiler to the value required for the high

temperature system.

3.5 Checks after commissioning

Once commissioning has been completed, check:

- the plumbing circuit for leaks

- that the heating system is pressurised

- that the main switch for the system works

- that the electrical connections are correct.

- the mixing valve opens and closes correctly.

For heat requests from a mixed system, check that the mixing valves open and close

correctly.

b

If even one of these checks provides a negative result, the system is to be

switched off and must not be started up again until the fault has been elimi-

nated.Maintenance

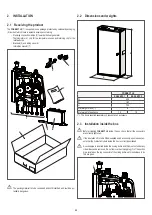

4 mAINTENANCE

4.1 Cleaning

Disconnect from the power supply before carrying out any cleaning operation by set-

ting the main switch to "off".

The panelling is to be cleaned with a damp cloth using soap and water.

If there are stubborn stains, use a cloth with a 50% water and denatured alcohol

mixture, or use specific products.

Dry carefully after cleaning.

a

Do not use abrasive products, benzene or trichloroethylene.

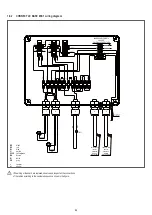

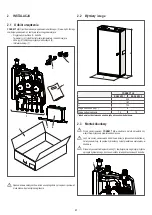

4.2 Draining the CONNeCT Le

Before starting draining operations, set the main switch to "off".

To drain the

CONNECT LE

:

- Close the shut-off cocks on the side of the system (if present)

- Connect a small pipe to the drain cock (1)

-

1

Using a CH11 wrench, open the cock (1) without unscrewing it completely

- After having drained the

CONNECT LE

close the cock (1) again.

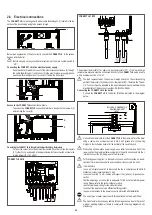

4.3 Checking the circulation units

When starting up for the first time and at least once a year, it is advisable to check

that the shaft of the circulation units rotate.This is necessary because, especially after

lengthy periods of inactivity, deposits and/or residue may stop it rotating freely.

Releasing the circulation unit shaft if necessary

To release the shaft, proceed as follows:

- insert a screwdriver (Phillips no.2) into the hole (1) of the circulation unit

- press (a) and turn (b) the screwdriver until the motor shaft releases

1

a

b

Take great care when carrying out this operation so as not to damage the components.

a

Do not run the circulation unit without water.

4.4 Checking the mixing valves

After a long period of inactivity, it is recommended that the correct function of the

mixing valves is verified. Manually act on them by using the control knob.