172 905 95 14-01

Declaration of conformity

Gas burner

Zertifi kat TÜV Süddeutschland

Certifi cate No

Burner

Certifi cate No

Burner

CE-0085 BT 0064

BFG1

CE-0085 BP 0352

BG550

CE-0085 AO 0230

BG100

CE-0085 BP 0353

BG550LN

CE-0085 AP 0623

BG150

CE-0085 AO 0084

BG600LN

CE-0085 AP 0624

BG200

CE-0085 BP 0354

BG650

CE-0085 AT 0192

STG120, STG146

CE-0085 AT 0313

BG700

CE-0085 AP 0625

BG300

CE-0085 AT 0314

BG800

CE-0085 AP 0626

BG400

CE-0085 BR 5754

BG950

CE-0085 AU 0156

BG450

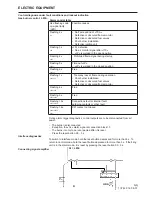

Document:

EN 676

DIN EN 60335-2-102

EU Directive

90 / 396 / EEC

Gas Directive

2004 / 108 / EC

EMC Directive

2006 / 95 / EC

Low voltage Directive

By conforming to the above-mentioned standards and

directives, the burner will receive the CE marking.

Genom att brännaren uppfyller ovannämnda standarder och

direktiv erhåller brännaren CE - märkningen.

Durch Übereinstimmung mit den oben genannten Normen und

Richtlinien erhalt der Brenner die CE-Kennzeichnung.

De par sa conformité aux normes et directives mentionnées ci-

dessus, le brûleur recevra le marquage CE de conformité.

Ljungby, Sweden, 141127 (27/11/14)

ENERTECH AB Bentone Division

Box 309

SE-341 26 Ljungby Sweden

Håkan Lennartsson

Enertech AB declares that the above-mentioned products

comply with the following standards or other normative

documents and meet applicable sections of the EU directive.

Enertech AB försäkrar under eget ansvar att ovannämnda

produkter är i överensstämmelse med följande standarder eller

andra regelgivande dokument och uppfyller tillämpliga delar i EU

direktiv.

Enertech AB erklärt hiemit, dass oben genannten Produkte mit

den folgenden Normen oder anderen normativen Dokumenten

übereinstimmen und die anwendbaren Teile der EU-Richtlinie

erfüllen.

Enertech AB déclare que les produits ci-dessus mentionnés sont

conformes aux normes ou autres documents normatifs suivants,

et répondent aux sections applicables de la directive EU.

Enertech AB Bentone Division is quality certified according

to SS-EN ISO 9001

Enertech AB Bentone Division är kvalitetscertifierat enligt

SS-EN ISO 9001

Enertech AB Bentone Division ist nach SS-EN ISO

9001qualitätszertifiziert.

Enertech AB Bentone Division a reçu la certification

d’assurance qualité SS-EN ISO 9001qualitätszertifiziert.

Содержание STG 146

Страница 2: ......

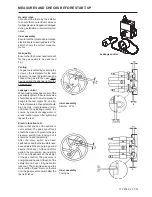

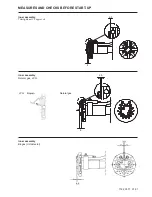

Страница 18: ...172 305 50 07 01 GENERAL INSTRUCTIONS Control of burner head Air adjustment Adjustment of inner assembly...

Страница 27: ......

Страница 28: ...Enertech AB P O Box 309 SE 341 26 Ljungby www bentone se www bentone com...