29

EN

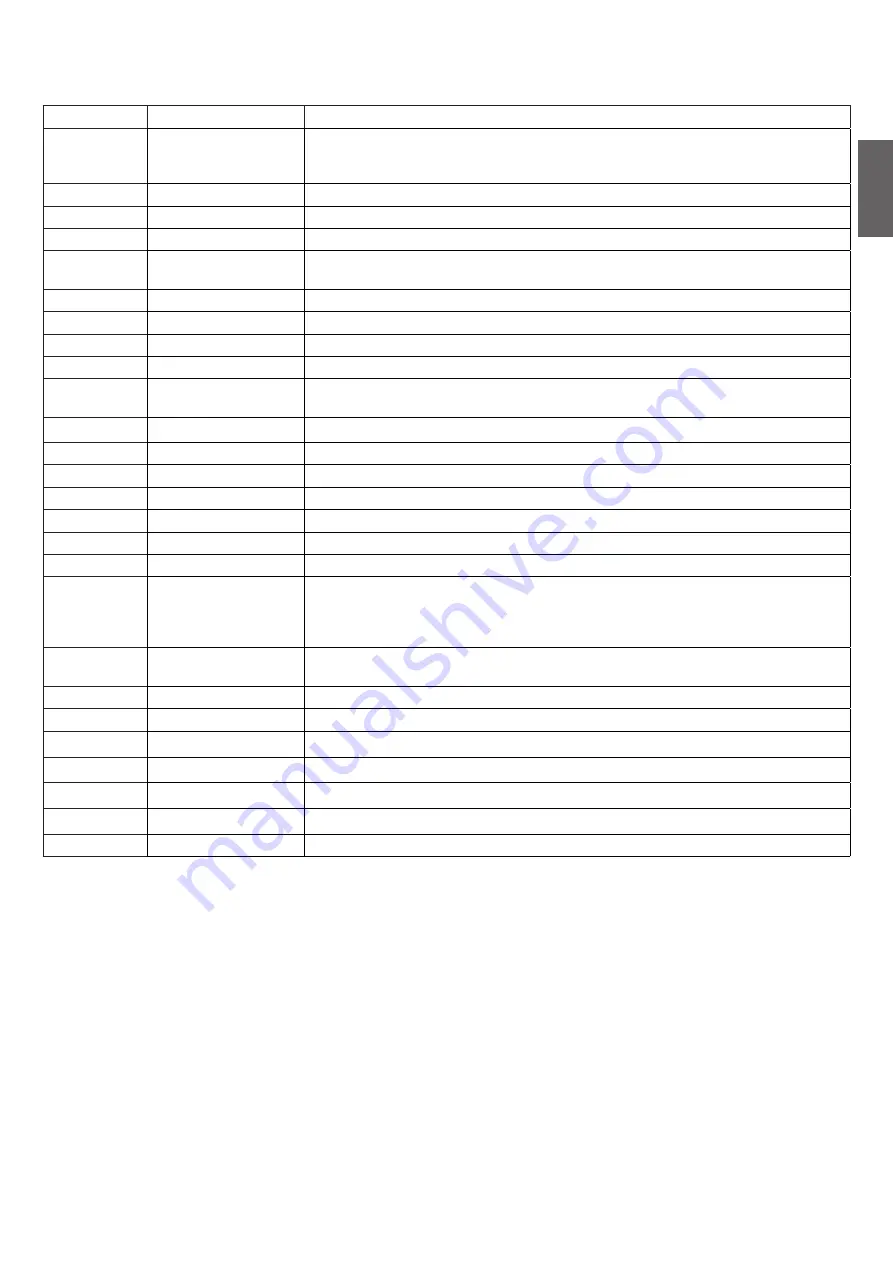

2) CP.BULL 15 OMI CONTROL UNIT

2.1) INPUT/OUTPUT FUNCTIONS

N° Terminals Function

Description

L-N-GND

Power Supply

Single-phase power input.

L: Phase - N: Neutral - GND: Ground connection to the motor housing.

Note: the ground connection must be done as shown in the diagram at page ???

U-V-W

Single-phase motor

Single-phase motor connection Phase-Common-Phase.

Lamp

Blinker

Blinker connection 230Vac 40W max or 115Vac 40W max (BULL 15 OMAI).

24 Vdc

24 Vdc

Auxiliary output power supply 24Vdc/500mA max.

SCA

SCA

N.O. Clean Contact (voltage free contact) to be used as open gate indicator 24 Vac 0.5 A

max, configurable through the logic SCA.

Phototest

Photo-test

Photocell test output, see figure 15

COM

COMMON

Common for all the input command.

OPEN

OPEN COMMAND

OPEN Input (N.O. contact).

CLOSE

CLOSE COMMAND

CLOSE Input (N.O. contact)

P.P.

STEP BY STEP COM-

MAND

STEP BY STEP Input (N.O. contact)

PED

PEDESTRIAN

PEDESTRIAN Input (N.O. contact)

STOP

STOP

STOP Input (N.C. contact)

PHOTO

OPEN PHOTOCELL

PHOTOCELL Input active only during opening phase

PHOTC

CLOSE PHOTOCELL

PHOTOCELL Input active only during closing phase

COM

COMUNE

COMMON for the limit switch

SWC

CLOSE LIMIT SWITCH

CLOSE Limit Switch Input (N.C. contact)

SWO

OPEN LIMIT SWITCH

OPEN Limit Switch Input (N.C. contact)

DAS/8K2

SAFETY EDGE

SAFETY EDGE Input

Resistive Edge (8K2): JP1 “DAS” close

Mechanical Edge (N.C.): JP1 “DAS” OPEN

The activation of the Safety Edge stops and reverses the movement of the leaf for 3s.

RADIO

RADIO RECEIVER

Plug-in connection for radio receiver ONE, to be used with the cable provided, see picture

18.

2CH

SECOND CHANNEL

Second radio channel output. N.O. contact (max 24Vac/dc 1A)

BRAKE

BRAKE RESISTOR

Brake resistor Input for the braking current dissipation.

P3

Not used

COM1

Not used

J7

Not used

J8

Not used

SW1

Dip1, Dip2

Keep in ON position

2.2) HOW TO CHECK CONNECTIONS

1) Cut off power supply.

2) Manually release the door/gate and push it for about half stoke. Lock the door again.

3) Restore power supply.

4) Send a step-by-step command through push-button <-> on the control unit (LCD display off). To stop the door/gate press <-> once

more.

5) The door/gate should open. If not, use the MINV logics to change the opening direction.

3) PROGRAMMING

The programming of the various functions of the control unit is carried out using the LCD display on the control unit and setting the

desired values in the programming menus described below.

The parameters menu allows you to assign a numerical value to a function, in the same way as a regulating trimmer.

The logic menu allows you to activate or deactivate a function, in the same way as setting a dip-switch.

Other special functions follow the parameters and logic menus and may vary depending on the type of control unit or the software

release.

Содержание CP.BULL OMI

Страница 2: ......