5)

Fill the container with the specified fuel - see chapter 3. Then

close the container carefully

to

prevent the intake of false air in the burner through the feed worm.

6)

Connect the boiler to the electrical power network (230V/50Hz) with the cable and the plug.

7)

If the boiler is equipped with automatic ignition

, don’t take further steps as the Boiler Control

Unit analyses the state of the boiler and takes further steps such as heating etc. (see the

separate Instruction Control Unit user`s manual). During heating up and subsequent operation

of the boiler, the fire door must be closed.

8)

If the boiler is not equipped with automatic ignition,

it is necessary to heat the boiler

manually (see the separate Boiler Control Unit users’ manual). Use the manual mode on the

Control Unit to transport the fuel to the combusting area. Leave the worm feeder switched on

until the fuel appears in the burner (approx. 1 cm under the grate rim). Then switch off the worm

feeder, place some kindling (paper, dry wood chips, solid alcohol or some other fire lighter

recommended for these purposes) on the top of the fuel, set it alight and wait until it begins to

burn (1-2 min.) Then add a small amount of specified fuel and switch on the ventilator. If the fire

extinguishes, repeat the whole process. Close the door and let the fire begin to burn (3-5 min).

7.2. Operation of the boiler

After the fuel begins to burn, the boiler switches to automatic operation (see the separate Control Unit

user manual) during which the ventilator and the cycling of the worm feeder are in operation. The main

information about the heating is shown on the display of the Control Unit.

In case of blackout of the supply voltage (230 V, 50 Hz), the Instruction Control Unit keeps in memory

the last data and after the voltage recovery, it returns to the previous state.

If the temperature of the heating water rises over 95°C, the emergency thermo regulator begins

operation and, independently of the Control Unit, the boiler will be cut off. The Control Unit then displays

overheating of the boiler.

The emergency thermo regulator can only be switched on again after the temperature sink

s about 20°C

below the set temperature. In this case, unscrew the black cap on the emergency thermo regulator and

press the red switch. Then return the black cap to its position.

To prevent an undesirable switching of the emergency thermo regulator, it is recommended to operate

the boiler at a maximum output water temperature lower than 80°C.

In case of frequent switching off, the boiler must be shut down and the cause of repeated overheating

must be established.

7.3. Boiler shutdown

Before the boiler is shut down, burning fuel must be ejected from the burner to the ashtray manually by

means of the worm conveyor. This operation is not necessary in case of short time repairs and if the

operator is present.

In case of a shut down longer than 12 hours

(e.g. cut out),

the container must be emptied

and if

there is a possibility that the water in the emergency extinguishing system can freeze, it is necessary to

empty the pressure tank as well.

IMPORTANT WARNINGS:

This appliance cannot be operated by persons (including children) who are not

physically, sensorially or mentally fit to do so and have insufficient knowledge and

experience needed in order to operate the boiler safely.

Children must not be left unattended in the proximity of a running boiler.

Due to danger of explosion or fire hazard caused by entry of flammable vapours in

the fire room, during any works that involve use of flammable substances (gluing of PVC,

painting with flammable paint etc.) the boiler must be shut down.

Содержание R100

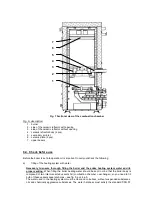

Страница 1: ...1 SERVICE AND INSTALLATION MANUAL FOR CENTRAL HEATING BOILER BENEKOV R100 ...

Страница 8: ...Fig 2 Basic dimensions of BENEKOV R100 boiler ...

Страница 9: ...Fig 3 Basic dimensions of BENEKOV R100 boiler with additional module of fuel bin ...

Страница 30: ...30 Declaration of conformity of boiler BENEKOV R 100 ...

Страница 31: ...31 Original ES declaration of conformity of boiler BENEKOV R 100 ...